Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

型号Model | GK-60 |

片状产量(kg/h) Tablet Capacity | 20~100 |

颗粒状产量 (kg/h) Granule Capacity | 5~40 |

颗粒细度(mm) Granule Diameter | 0.5~3 |

最大压力(KN) Max Pressure | 294 |

侧密封压力(KN) Side Seal Pressure | By manual |

送料电机(KW) Feeding Motor | 0.55 |

轧辊电机(KW) Roll Motor | 3 |

制粒电机(KW) Granulating Motor | 0.75 |

送料螺杆转速 Feeding Screw Speed | 6~65 |

压轮转速 Roll Speed | 4~25 |

压轮外形尺寸(mm) Roll Size | φ150*60 |

外形尺寸(mm) Overall Size | 1085*650*1600mm |

重量(约kg)Approx. Weight | 750 |

Video Link:

https://youtu.be/Z6byLm5L2v0?si=qrRAOUNmgadTufRl

https://youtube.com/shorts/4jlH1sde3jE?si=OAT1OO8yRdj2APk3

https://youtube.com/shorts/sAC6nygkAn0?si=bAKHELfBjjGFAD6C

Dry Granulator: Concept and Core Working Principle

I. Basic Concept

A dry granulator is a process equipment that directly compacts dry powder into dense flakes or strips and then crushes and shapes them into uniform granules—without adding any liquid binders.

Its core working principle is summarized as "first compaction, then crushing and granulation", which is mainly divided into two key stages:

1. Compaction

Two parallel, precision-machined pressure rollers (usually with multiple grooves or smooth surfaces) rotate toward each other under enormous hydraulic or mechanical pressure.

Dry powder is forcibly fed into the nip zone between the two rollers via a feeding system (e.g., screw feeder).

Under ultra-high linear pressure, powder particles are compressed: intermolecular forces between particles are strengthened, and plastic deformation or brittle fracture may occur simultaneously. This process expels air from the powder bulk, forming dense, solid flakes or compacts with stable structural integrity.

2. Crushing & Granulating

The hard compacts produced in the compaction stage are then transferred to a crushing and granulating system (typically consisting of a primary crusher and a secondary granulator, equipped with rotating blades and screens inside):

The compacts are first shattered into small lumps by the primary crusher’s rotating blades.

These lumps then pass through the secondary granulator’s screen, where they are further sheared and abraded into uniformly sized granules.

The final particle size of the product is precisely controlled by adjusting two key parameters: the aperture of the granulator’s screen and the rotational speed of the internal blades.

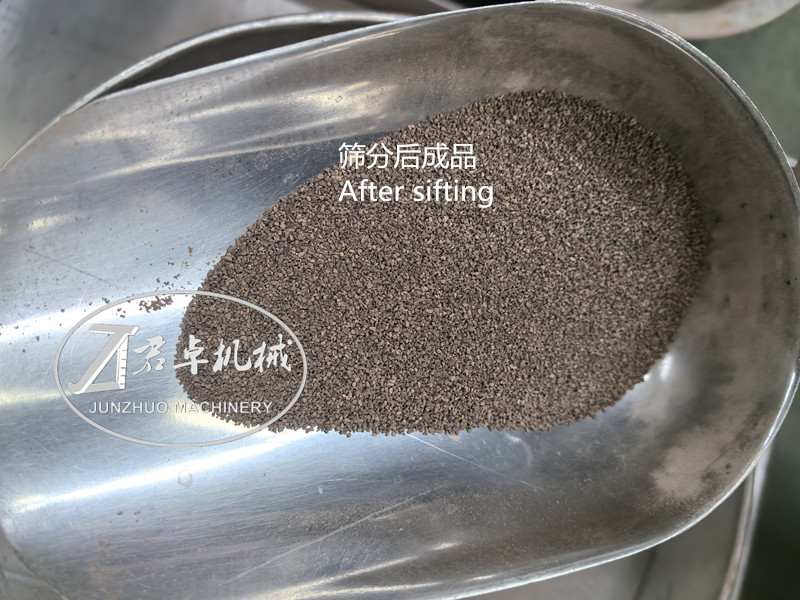

Testing results:

Raw material is 15kg, testing time is 20 minutes, we got the final granules about 50%.

Then the powder after sifting tested again, testing time is 15 minutes, we got the final granules about 61.7%.

By continuing to use the site you agree to our privacy policy Terms and Conditions.