Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

Which Fields Can We be Used in?

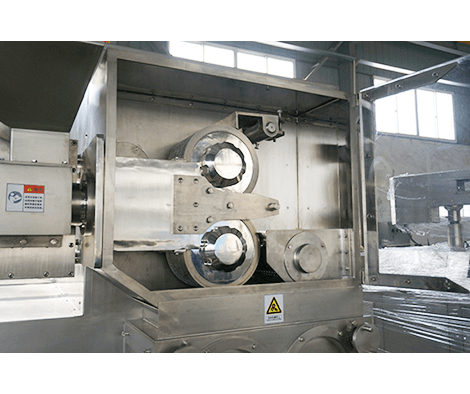

In pharmaceutical industry, roller compaction has become the method of choice for dry granulation. Because of its reasonable design, the process technology can be almost completely disassembled without special tools. The movable design provides great flexibility during compaction feasibility studies and allows an easy maintenance.

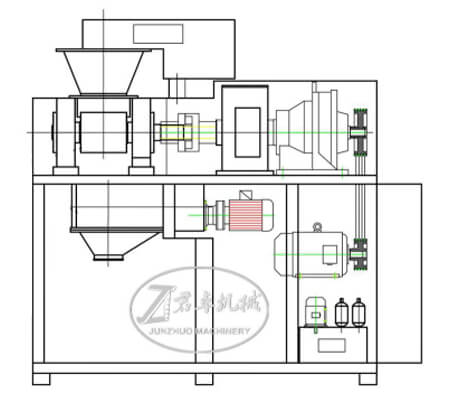

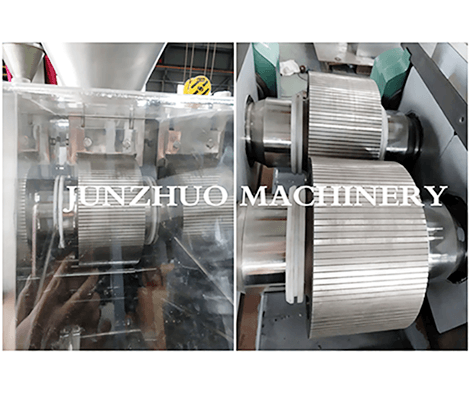

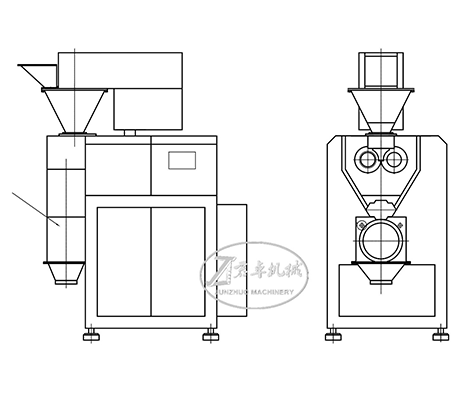

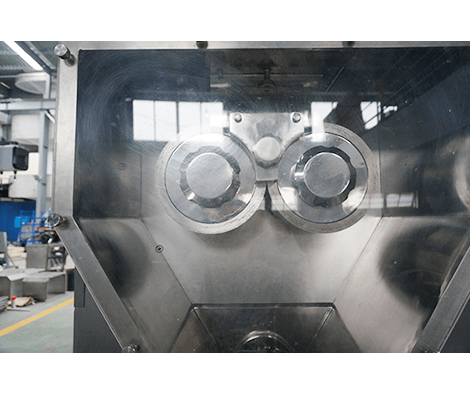

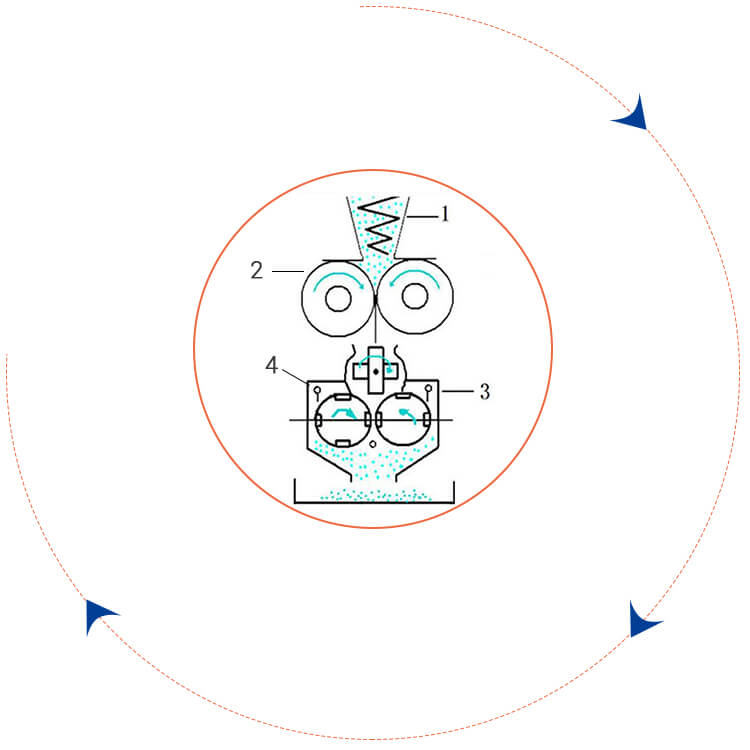

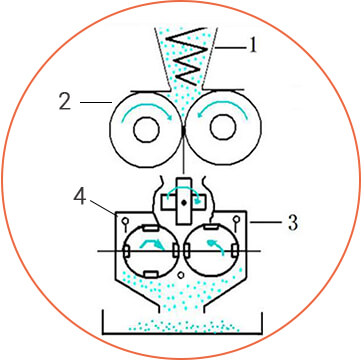

Roll Compactor (RC Machine) , we usually called it dry granulator in Chinese , it is a versatile densification and dry granulation machine that produces uniform compacted sheets with consistent hardness and increased density by compacting powdered material between two uniquely designed rolls.

+86-0510-86382380

+86-0510-86382380 ENGLISH

ENGLISH