Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

Which Fields Can We be Used in?

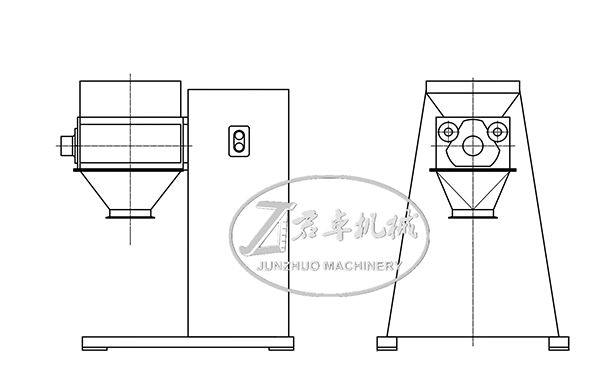

Oscillating granulator is used for gentle homogenization, size reduction, grading and sieving of dry, sensitive powders and granules in pharmaceutical, chemical and food industries.

Oscillating granulator plays an important role in the process of granulation in tablet making as quality of tablet is determined by the virtue of the granules used for its compression. Oscillating granulator can be used for wet and dry aspect of the granulation process quality of granules are better compared to other processing machineries like multi mill, comminuting mill etc.

+86-0510-86382380

+86-0510-86382380 ENGLISH

ENGLISH