jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

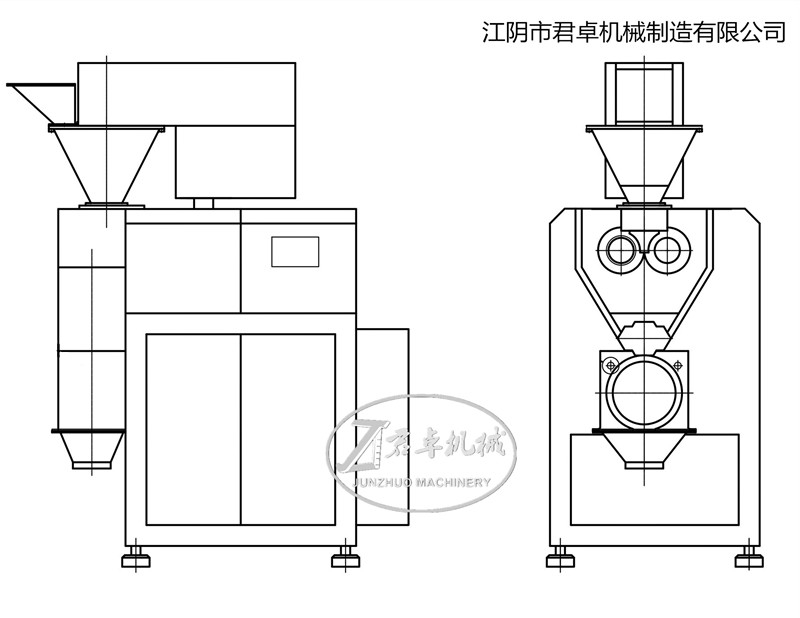

This roller compactor is a clean type, it is easy to clean and maintaince. A vacuum conveyor, dust collector and vibrating sifter is available. It is vertical feeding type, the capacity is 100 to 150kg/h.

Compared with wet granulation, roller compaction requires less equipment, lower cost, less space, and more environmental protection. At present, the roller compactor is widely used in the pharmaceutical, food, chemical and other industries, especially for the materials which are easy to decompose and agglomerate.

Pharmaceutical industry-- granules for traditional Chinese medicine, granules for filling capsules of antibiosis substances, granules for direct beating of antibiosis substances, animal medicinal granules, powder dialysis preparations and so on.

Food industry - granule for condiment and spicy condiment, granule for snack making, granule for health food.

Chemical industry and others - cosmetics, pesticides, chemical industry drugs, animal feed, detergent

Optional Features:

Available different type of rolls - 1. Plain 2.Corrugated 3.Knurled.

Contact part made by AISI 316L, Non-contact part made by AISI 304.

A vibration sifter, which can filters small or undersize granules for re-granulation

An automatic suction conveyer or screw conveyor for the charging or recycling of powder or granules

PLC Controls with HMI touch screen.

Working platform to help observe the feeding hopper.

Dust collector to clean the environment.

Vibrating screen sieves (different sizes)

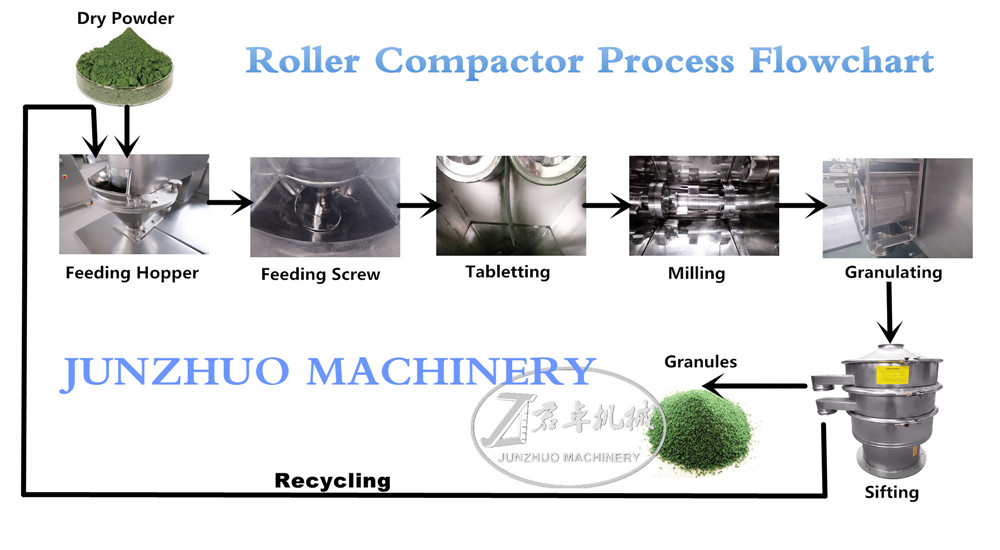

The dry powder is placed into the inlet feed hopper of the Roller Compactor. Then the powder goes through the feed hopper/ lump breaker to the press roller vertically. Once the powder is pressed against the roller press then the powder must be scrapped by a scrapper beneath the press roller. The powder should than proceed to the granulator unit. The roller compactor must be equipped with a programmable control system, and adjustable sieve size. Roller compaction involves squeezing the continuous stream of powder blend between two pressure rollers, producing a sheet of material, called “flake”. In conventional method, the intermediate product (sheet/flake) are broken to produce granular material using suitable milling technique. In subsequent stage, the desired size fraction of granule is separated out from granular material by sieving.

Clean type one is suitable for every application, just depends on your requirement and budget. (GK30 to GK200)

| Model | GK-30 | GK-60 | GK-80 | GK-100 | GK-120 | GK-150 | GK-200 |

| Output of sheet (kg/h) | 3~10 | 20~100 | 80~150 | 120~200 | 150~250 | 200~350 | 250~500 |

| Output of granule (kg/h) | 0.5~2 | 5~40 | 20~50 | 40~100 | 75~100 | 100~150 | 100~300 |

| Granules diameter(mm) | 0.5~3 | 0.5~2.5 | 0.5~4 | 0.5~4 | 0.5~4 | 0.5~4 | 1~5 |

| Total power(KW) | 2.5 | 4.5 | 8.5 | 12.5 | 12.5 | 18 | 24 |

| Feed Screw Speed(rpm) | 6~33 | 6~65 | 6~60 | 6~60 | 6~60 | 5~50 | 5~50 |

| Roll speed(rpm) | 4~25 | 4~25 | 4~25 | 4~25 | 4~25 | 4~25 | 5~22 |

| Overall size (mm) | 880*550*1300 | 1085*650*1600 | 1600*1000*2300 | 1800*900*2300 | 1880*1020*2300 | 2350*1850*2550 | 2500*2150*2750 |

| Approx. weight(kg) | 550 | 750 | 1800 | 2000 | 2300 | 5500 | 6500 |

1. No water or any organic solvents. Therefore, this method is especially attractive for drugs, which are moisture or heat sensitive.

2. Suitable for compounds that either have a low melting point or degrade rapidly during heating, as the method does not involve any drying step.

3. Forming porous tablets thus allowing water to penetrate more easily into the tablet. This leads to improved disintegration behavior of tablets.

4. Roll compaction technique provides an efficient and easily automated process, which is environmentally friendly.

5. Low operational cost.

6. Dust problems are minimized or avoided and the die filling during tableting is improved.

7. Roll compaction/dry granulation can be used, if the drug or the excipient is poorly flowing or sensitive to heat or moisture.

8. It can also be used for densification of powders prior to encapsulation.

9. Control particle hardness and provide granule integrity during conveying and processing steps.

10. Control dust and reduce environmental risk, waste and cross-contamination.

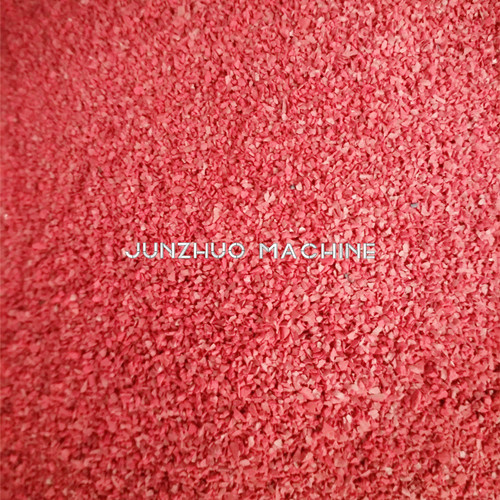

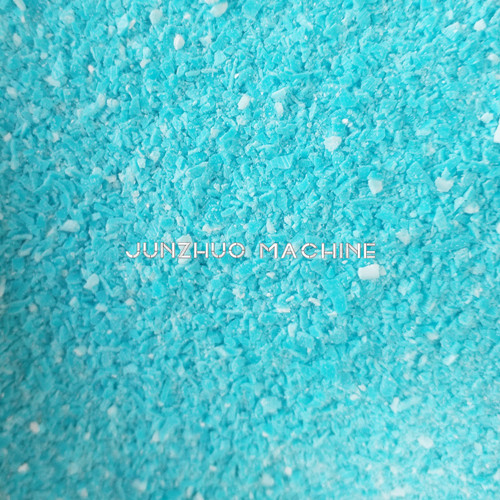

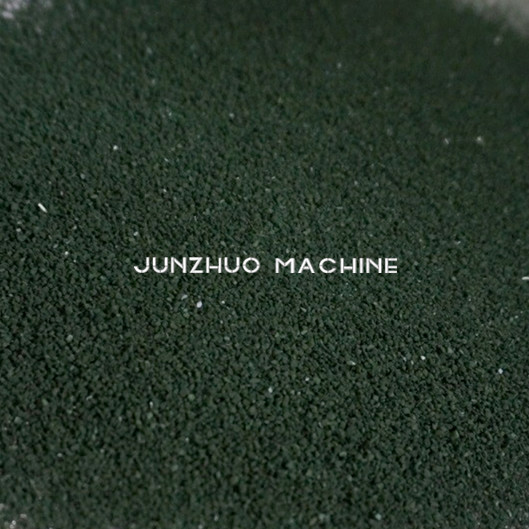

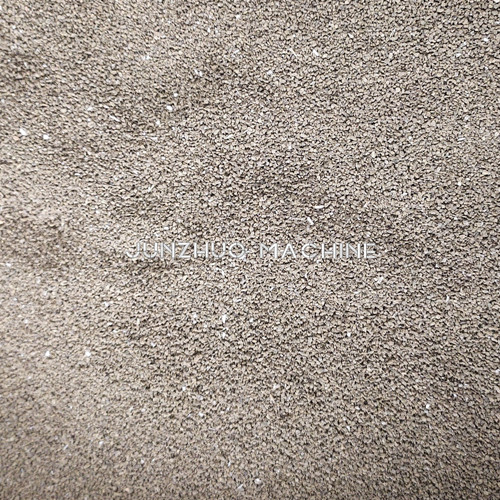

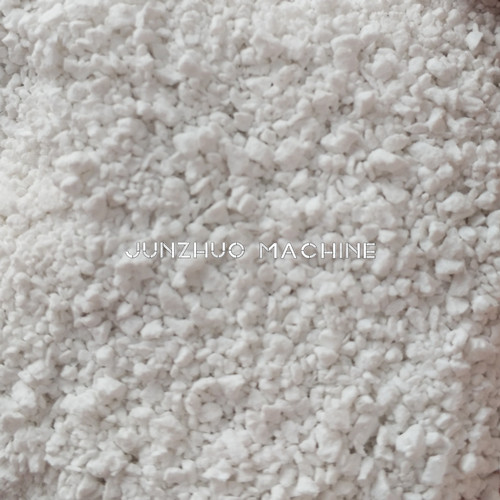

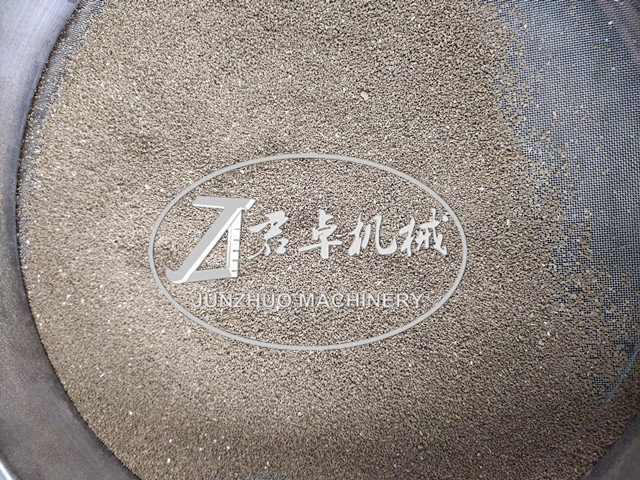

After granulation(Different materials in different application). It is ok for testing raw material if you can send sample to us.

Food Color |  Catalyst |  Chinese Herb |

Ginseng |

|  SiO2 |

All the parts which contacted with material can be taken off for completely clean, so it is very easy for daily maintenance.

Before |  Cleaning |

Sheets |  Granules |

By continuing to use the site you agree to our privacy policy Terms and Conditions.