Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

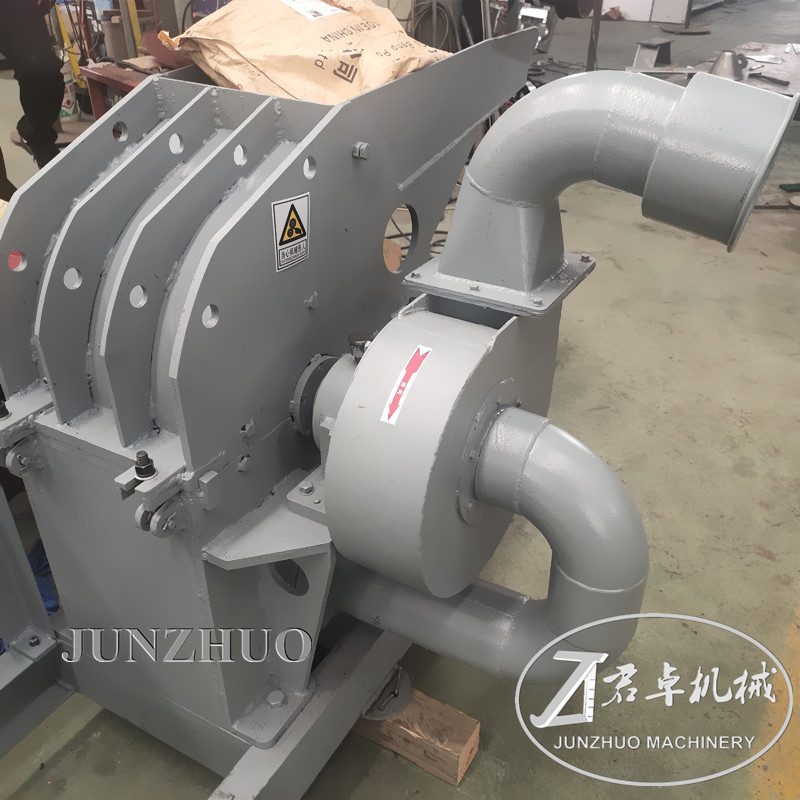

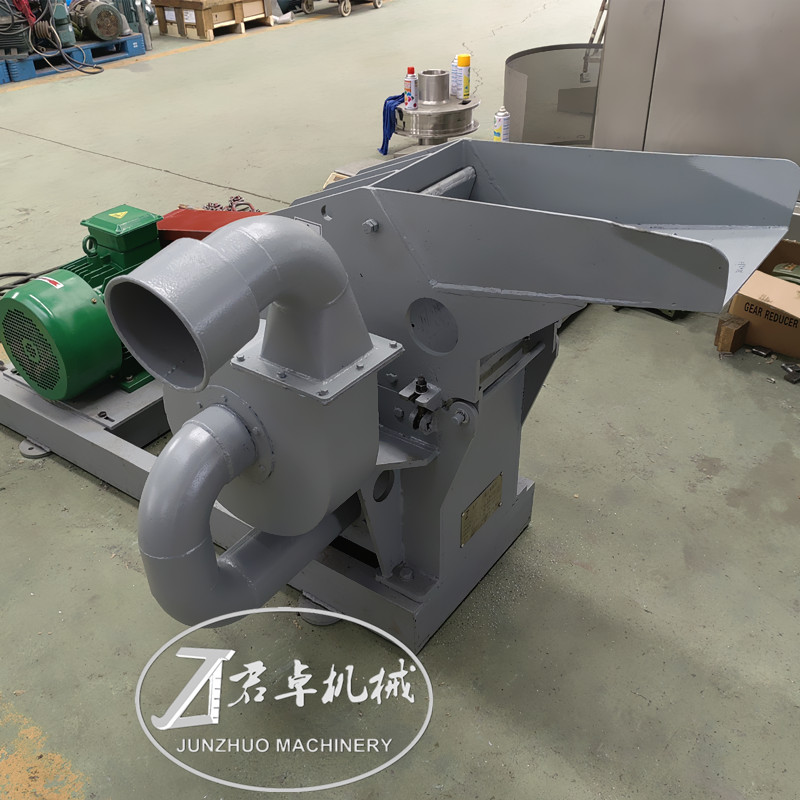

The name "negative pressure suction hammer mill" precisely describes a complete crushing system that uses negative pressure airflow for conveying and operation. It emphasizes the working mode of the system (negative pressure suction and delivery) and the core crushing principle (hammer type). This is actually the specific application and systematic extension of the "self-priming crusher" on the hammer crusher.

The hammer self-priming pulverizer is a highly efficient and universal automated pulverizing equipment known for its "impact pulverization". It perfectly meets the demand for large-scale, dust-free crushing of blocky, granular and fibrous materials in industries such as feed, grain and traditional Chinese medicine.

If the materials you need to process meet the above characteristics and you pursue high output and operational convenience, then the hammer self-priming pulverizer is a very ideal choice. Just pay attention to the maintenance characteristics of the wear of its vulnerable parts.

The outstanding advantages of the hammer-type self-priming crusher

High crushing efficiency and wide applicability

The high-speed impact force of the hammer pieces is highly suitable for crushing materials with various properties such as brittleness, fibrous nature, and toughness, effectively handling everything from grains and feed to Chinese medicinal materials and wood chips.

Convenient particle size adjustment

Just by replacing the annular screens with different hole diameters, the fineness of the product's crushing can be easily controlled.

Built-in air selection, improving efficiency and reducing consumption

When the hammer rotates, it is like a fan itself, capable of generating a powerful airflow. This airflow is not only used for self-priming feeding but also can promptly "blow out" the fine powder from the screen in the crushing chamber, preventing excessive crushing of the material inside the machine. As a result, energy consumption and temperature rise are reduced, and output is increased.

Good safety

The movable hammer pieces can avoid hard objects such as iron and stone, reducing the jamming and motor burning phenomena during the crushing process.

Typical application scenarios

This type of model is particularly common in the following industries:

Feed processing industry: The absolute main model. It is used for crushing various feed raw materials such as corn, soybean meal and straw.

Grain processing industry: Crushing grains, beans, etc.

Biomass energy industry: Crushing wood chips, straw, etc. as fuel or raw materials.

Traditional Chinese medicine industry: Crushing plant roots, stems, leaves and other traditional Chinese medicinal materials.

Limitations

Wear and tear issue

Hammer pieces and screens are vulnerable parts. Especially when handling materials with high hardness or strong abrasives, they wear out quickly and need to be replaced regularly, resulting in relatively high maintenance costs.

Temperature rise issue

Although air selection is helpful for cooling, high-speed impact and friction still generate a considerable amount of heat. It should be used with caution for heat-sensitive materials (such as certain drugs and high-sugar materials).

Not suitable for extremely hard materials

Although it can avoid foreign objects, long-term crushing of extremely hard materials such as metal ores and cement clinker will accelerate wear sharply and is not suitable for such applications.

By continuing to use the site you agree to our privacy policy Terms and Conditions.