Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

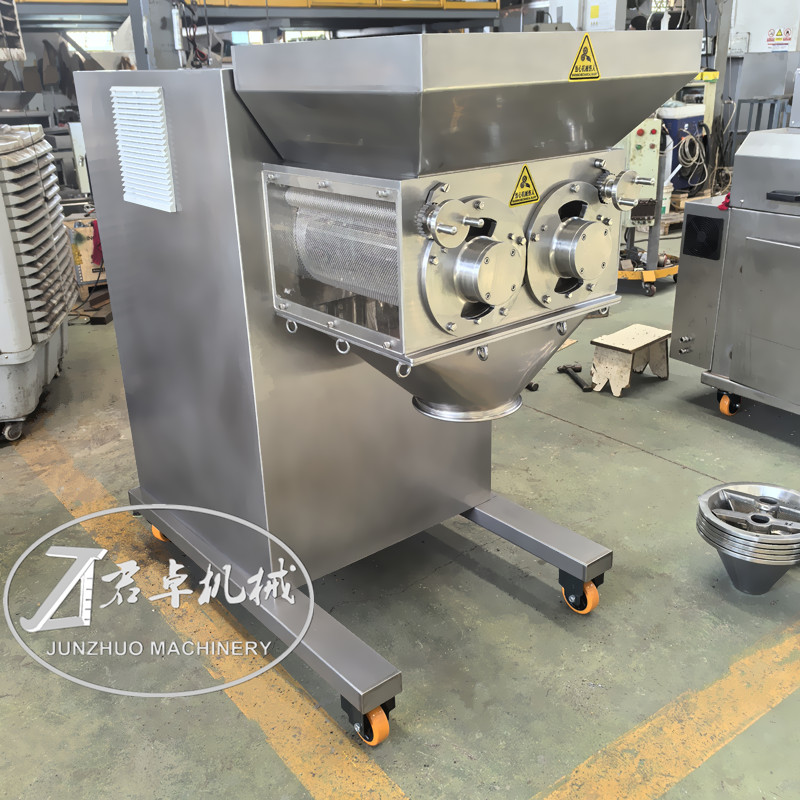

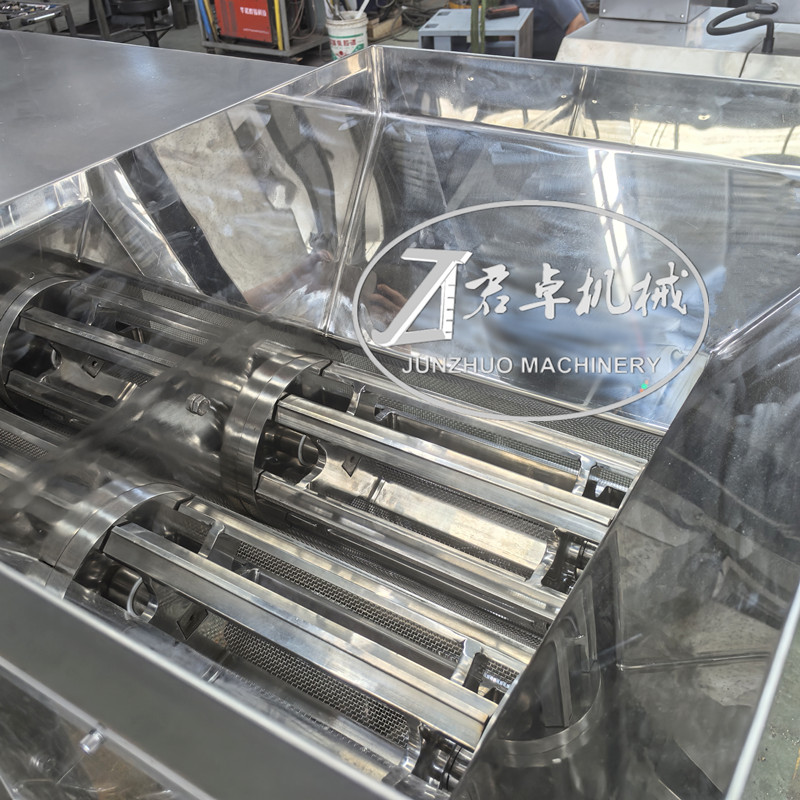

The double rotor oscillating granulator is a typical representative of the development of oscillating granulation technology toward higher efficiency and larger scale. Derived from the classic single rotor oscillating granulator, this high-performance model is mainly designed to significantly improve production efficiency and meet the requirements of larger-batch production. It retains the working principle and all advantages of the single rotor model while achieving a leap in production capacity through structural innovation. It keeps the advantages of the oscillating granulation technology—such as high-quality granules, wide applicability, and simple operation—it solved the problem of production capacity through the parallel design of two working units. It is an ideal choice for many enterprises to upgrade their production capacity.

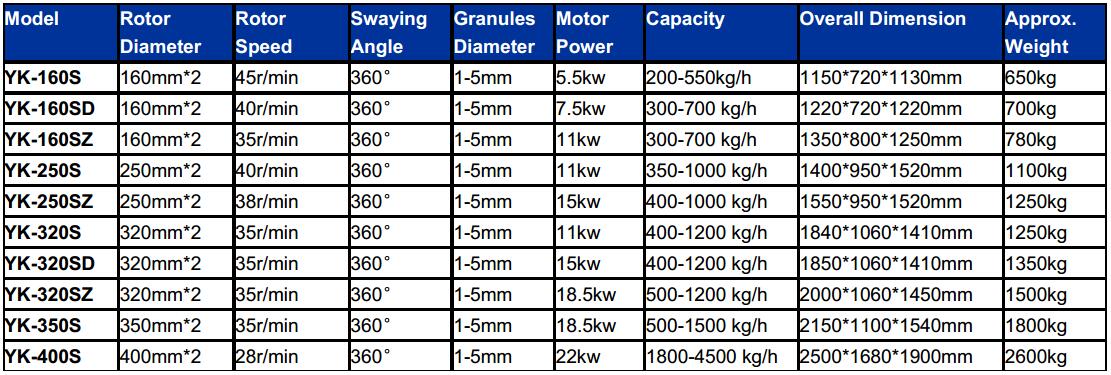

The YK Series Double Rotor Granulator covers a full range of capacities from 200kg an hour up to 4500kg an hour, each of the granulating machines provides a convenient and cost effective way of turning powders into granules in the pharmaceutical, food, chemical ceramics or related industries. Suitable for wet and dry granulation, these oscillating granulators also can be used for breaking down agglomerates into granules.

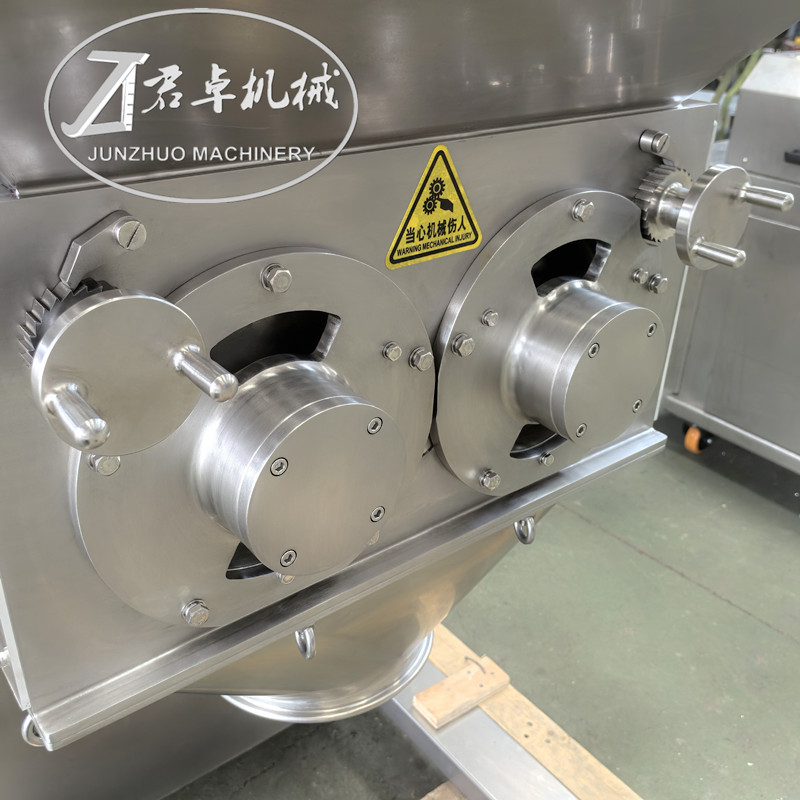

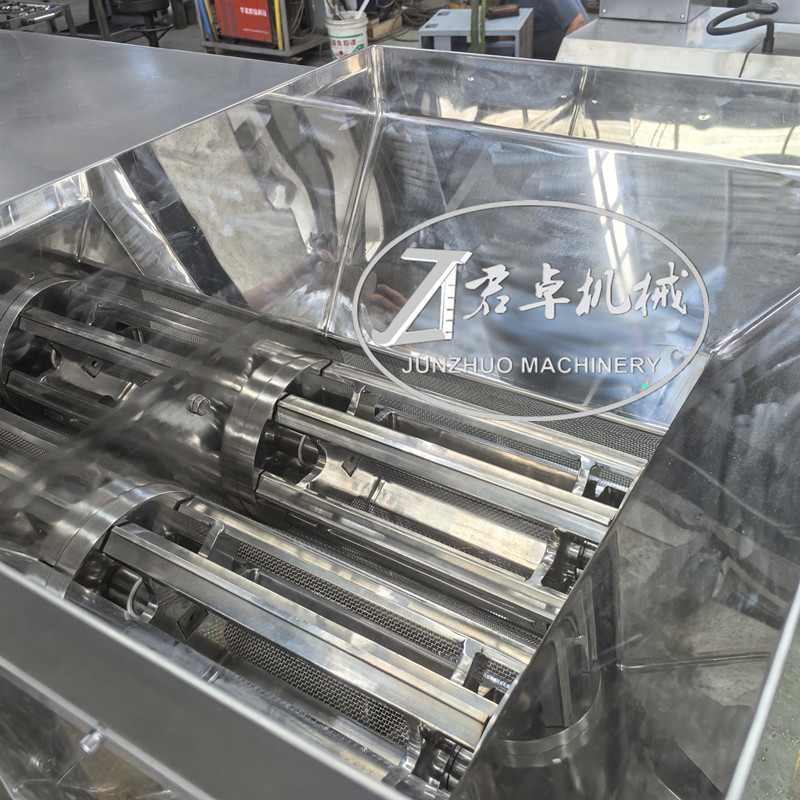

The YK Double Rotor Series consists of the YK160S, YK250S, YK320S, YK350S and YK400S, with the number denoting the diameter of the machine’s roller. They each work on the same principle, involving an oscillating metal cylinder that acts against an easily changed metal mesh. With powerful motors, adjustable speed, and carefully engineered oscillation for maximum efficiency and minimum energy requirement, these machines produce granular materials of the highest quality and consistency. Small amounts of active ingredients and the liquid binder that locks the powder as granules to prevent segregation.

All granulators in the series are built from stainless steel, and constructed to meet GMP standards. They are simple to operate and maintain, easy to clean, and designed to satisfy the stringent hygiene requirements needed for food production. They are also rugged and durable, with minimal maintenance needs, and will provide reliable operation for many years into the future.

Working smoother with the design of two groups of rotors, which can improve capacity effectively. We also can provide ODM&OEM production.

By continuing to use the site you agree to our privacy policy Terms and Conditions.