Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

I. Main Application: Enabling Physical Form Transformation of Materials

This is the most direct and fundamental function, which involves processing powdery, lumpy, or flaky materials into uniform granules.

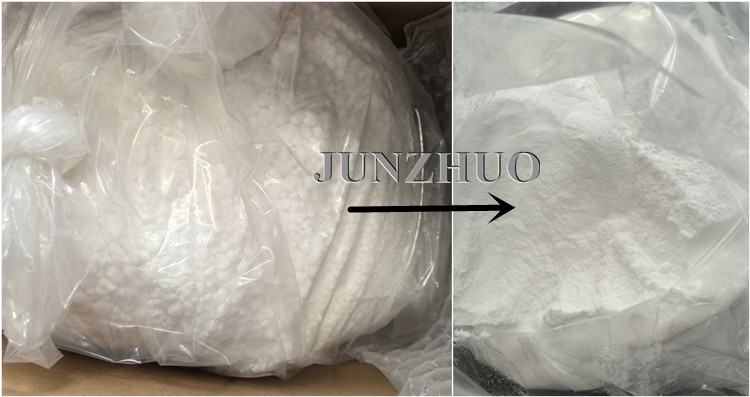

Powder → Granules (Wet Granulation):

This is the most primary application. In the wet granulation process, the mixed wet soft material (in paste or lump form) is processed through a granulator to produce uniform-sized wet granules, preparing for the subsequent drying process.

Lumps/Flakes → Granules (Dry Granulation):

Dry agglomerated materials, or unqualified large tablets and lumps generated after tableting or dry granulation, are crushed and re-granulated to obtain uniform dry granules, which are used for recycling or further processing.

II. Optimization Effect on Production Processes

The transformation of physical form brings a series of key process advantages, which is the reason why granulators are indispensable.

Improving Fluidity to Ensure Smooth Subsequent Processes

Problem: Fine powder has very poor fluidity, and it is prone to adhesion and bridging. This leads to uneven feeding in subsequent processes (such as tableting and capsule filling), resulting in tablet weight variation or unqualified filling volume.

Function: The granules obtained after granulation are like small "balls" and have much better fluidity than powder. This ensures that materials enter the tablet press or capsule filling machine uniformly and smoothly, serving as a key prerequisite for the smooth progress of high-speed automated production.

Enhancing Compressibility to Improve Tableting Quality

Problem: When powder is compressed into tablets, there is a large amount of air between the particles, which easily causes phenomena such as "capping" (top cracking) and "lamination" (layer cracking), resulting in defective tablets.

Function: Granules have better compression properties than powder. The gaps between granules are more uniform; during the tableting process, air is more easily discharged, and the material distribution is more even. This enables the production of tablets with higher strength, smoother appearance, and less tendency to crack.

Preventing Component Separation to Ensure Uniform Content

Problem: A powder mixture composed of raw materials with different densities and particle sizes is prone to vibration-induced separation (segregation) during transportation and processing. This leads to uneven distribution of active ingredients in the final product, affecting efficacy or quality.

Function: By granulating the wet soft material made from various components together, different components are "locked" inside each granule, forming a microcosmically uniform unit. This greatly reduces the risk of component separation in subsequent processes and ensures the uniformity of product content.

Controlling Bulk Density to Adjust Product Volume

Function: By selecting screens with different apertures and adjusting the blade speed, the size and compactness of the produced granules can be controlled, thereby indirectly controlling the bulk density of the material. This is crucial for controlling the size of the final tablets or the filling volume of capsules.

Optimizing Drying Efficiency to Save Energy and Reduce Consumption

Problem: If wet soft material is directly dried, the drying time will be significantly prolonged and energy consumption will increase due to agglomeration and surface crusting.

Function: The uniform wet granules formed after granulation have a larger specific surface area, which allows hot air to penetrate the material layer more easily and moisture to evaporate more readily. This significantly shortens the drying time, improves drying efficiency, and reduces energy costs.

III. Quality Control Effect on Products

Ensuring Product Uniformity: Producing granules with a concentrated particle size distribution serves as the physical foundation for ensuring the consistent quality of each tablet or capsule.

Reducing Dust to Improve the Production Environment: Granular materials generate much less dust than powdery materials. This is beneficial for protecting workers' health, reducing the risk of cross-contamination, and complying with safety production and GMP (Good Manufacturing Practice) requirements.

Facilitating Subsequent Coating: The uniform surface of granules makes it easier for the coating solution to adhere evenly, forming a stable and aesthetically pleasing coating layer.

In the end

A rapid granulator(cone mill) is by no means just a "granule-making" machine; it is a key hub equipment in the production of modern solid preparations (such as tablets and capsules).

By converting materials into uniform granules, it fundamentally solves problems such as poor fluidity and easy separation of powder. This optimizes the efficiency and stability of subsequent core processes like tableting, filling, and drying, and ultimately ensures that each batch of products meets the predetermined high-quality standards under large-scale production.

In simple terms, its role is to "connect the preceding and the following" — it receives the mixed materials and provides the most suitable intermediate for subsequent drying and forming processes, making it one of the core links to ensure the efficient and high-quality operation of the entire production line.

By continuing to use the site you agree to our privacy policy Terms and Conditions.