Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

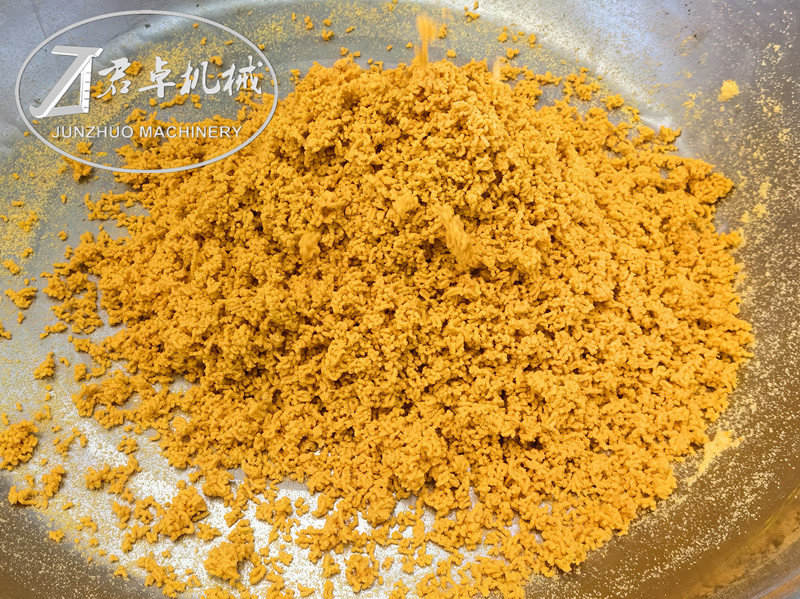

The rotary granulator is a classic wet granulation device. Based on the principle of centrifugal extrusion, it converts wet powder mixtures (mixed with binders) into uniform granules. Its applications are extremely wide-ranging, primarily focusing on industries that require converting powders into granules of specific particle sizes.

I. Core Application Industries

1. Pharmaceutical Industry (Primary Application Field)

This is the largest and most critical application field for rotary granulators, serving as one of the core devices in solid preparation production.

Tablet Production: Prepares granules for the tableting process. Granulation improves the fluidity, compressibility, and content uniformity of powders, making it an indispensable step before tableting.

Capsule Production: After powders are converted into granules for capsule filling, the fluidity of the contents is enhanced, ensuring consistent filling weight and reducing dust.

Granule/Infusion Production: Directly produces granules as end products, such as cold granules and traditional Chinese medicine (TCM) granules.

Coated Granule Preparation: The uniform granules produced serve as the core (mother core) for pellet coating.

2. Food Industry

Instant Drinks: Manufactures instant products like coffee, milk powder, soybean milk powder, and fruit juice powder. Granulation accelerates dissolution, improves fluidity, and facilitates packaging and preparation.

Seasonings: Produces granules for chicken essence, soup bases, and solid soy sauce powder. Granulation prevents caking, making the products easier to use and dose accurately.

Candies and Sweeteners: Used to produce certain types of candy bases or directly granulate sweeteners (e.g., aspartame).

3. Chemical Industry

Pesticides and Fertilizers: Converts pesticide technical materials or fertilizer powders into granules. This significantly reduces dust emissions, lowers toxic hazards, improves fluidity during application, and prevents segregation and caking.

Dyes and Pigments: Granulation simplifies transportation and metering, while reducing dust pollution during use.

Detergents: Produces granules for laundry detergent and dishwasher detergent.

Catalysts: Converts catalyst carriers and active ingredients into granules of specific strength for use in chemical reactors.

4. Other Industries

Ceramic Industry: Granulates ceramic powders to improve their mold ability during pressing.

Metallurgical Industry: Used for preprocessing metal powders.

Research Institutes: Applied in process research and development of new materials and formulations.

II. Application Advantages of Rotary Granulators (Why Choose Them?)

In its application fields, the rotary granulator offers the following advantages over other granulation methods:

High Granule Density and Strength: Formed by extrusion, the granules are denser, more robust, and produce less fine powder.

Uniform Particle Size: Particle diameter is controlled by the screen, resulting in highly uniform granules with a concentrated particle size distribution.

Large Processing Capacity and High Efficiency: Suitable for continuous production of small-to-medium batches, with high operational efficiency.

Broad Material Adaptability: Can handle materials of various properties, especially those with moderate viscosity.

Simple Operation and Easy Control: Features a relatively simple structure, easy operation, and convenient adjustment of process parameters (e.g., screen mesh size).

Easy Cleaning and Maintenance: Modular design allows easy disassembly and cleaning, making it suitable for scenarios requiring frequent product changeovers.

III. Key Process Points in Application

To ensure successful use of the rotary granulator, mastery of the following key points is essential:

1. Preparation of Soft Mass

This is the first and most critical step for successful granulation. The moisture content of the powder-binder mixture (binders such as ethanol, water, or starch paste) must be optimal—described by the empirical standard: "forms a ball when squeezed, disperses when touched."

Too Wet:Clogs the screen sieve.

Too Dry: Fails to form granules, producing excessive fine powder.

2. Screen Selection

The screen’s aperture (mesh size) directly determines the final particle size. It must be selected based on product requirements. Additionally, the screen material (usually stainless steel) and strength must meet process standards.

3. Machine Speed Control

Rotation speed affects extrusion force and production efficiency:

Too Fast: May generate heat (drying out materials) or cause irregular granule shapes.

Too Slow: Results in low efficiency.

4. Binder Selection and Addition

Different binders and addition methods significantly impact granule properties. The choice must be based on material characteristics (e.g., solubility, stability to heat and moisture).

Summary

The rotary granulator is a versatile wet granulation device with extremely wide applications. Due to its simple working principle, reliable granule quality, and easy operation/maintenance, it holds a solid position in powder processing across the pharmaceutical, food, and chemical industries.

For enhancing the usability of end products or meeting process requirements for intermediate steps, the rotary granulator is a reliable and efficient choice to make powders into uniform, high-fluidity granules.

By continuing to use the site you agree to our privacy policy Terms and Conditions.