Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

GK60 Dry Granulator The GK-60 roller compactor is a clean type, a vertical product flow system uses a tapered feed screw to deliver the material to the fully contained compaction zone of the cantilevered rolls, increasing product yields and minimizing product fines. Roll compactor utilizes a unique roll system to compact powders into sheets or briquettes. The compacted sheets are milled to produce granules of a specific size. |

Tabletting The material in form of powder passes through the two counter rotating rolls of roller compactor under very high pressure. As the volume decreases through the region of maximum pressure, the material is formed into a solid compact sheet or flakes of ingredients. These flakes or compact sheet of ingredients are reduced in size to obtain the desired grain size. The machine takes extra care to prevent the generation of fine during this process. |

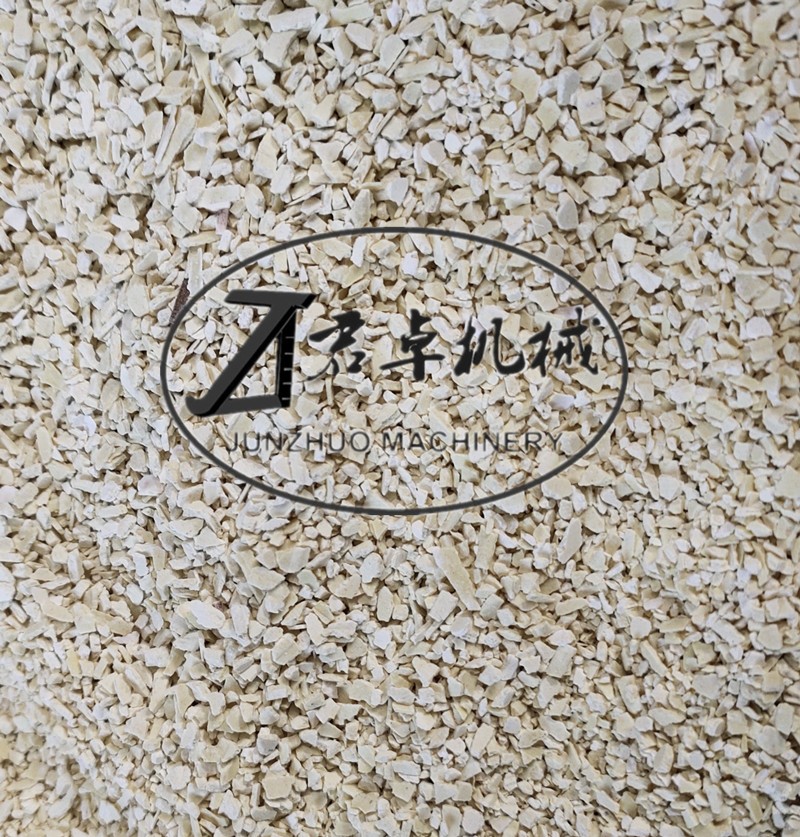

Final Granules The granule size is adjustable by changing screen sieves. JUNZHUO MACHINERY supply all the sizes as your requirement. |

Technical Data

1.Capacity:20-100kg/h(Output of Sheet)

5-40kg/h(Output of Granule)

2. Output size:0.5-2.5 mm

3.Feed Screw Speed:6-65 RPM(Frequency control)

4.Roller Speed:4-25 RPM (Frequency control)

5. Roller Size: φ150*60

6. Granulating motor power: 0.75KW(Frequency control)

7. Feeding motor power: 0.55KW

8. Roller motor power:3KW

9. Max. Pressure:160KN

10.Overall Diameter: 1085*650*1600mm

11. Approx. Weight:750KG

Working video: https://youtu.be/Tqruc298gzg

By continuing to use the site you agree to our privacy policy Terms and Conditions.