Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

Comparison between Oscillating Granulators and Rotary Granulators

Oscillating granulators and rotary granulators are two classic wet granulation devices, with significant differences in working principles, structures, and applicable scenarios. Below is a detailed comparison, supplemented by a table for intuitive reference:

Difference Comparison Table

Detailed Analysis & Selection Guide

Characteristic Dimension | Oscillating Granulator | Rotary Granulator | Difference Interpretation |

Working Principle | Reciprocating oscillating extrusion | High-speed rotational centrifugal extrusion | The most fundamental difference in motion mode, which determines all other variations. |

Motion Mode | Roller performs reciprocating oscillation (<360°) | Roller performs continuous high-speed rotation (360°) | Oscillation is like "grinding with a pestle"; rotation is like "spinning to dehydrate." |

Core Force | Mechanical extrusion force | Centrifugal force + extrusion force | Rotary granulators combine two forces, resulting in stronger material processing capability. |

Production Efficiency | Lower | Higher | The continuous high-speed motion of rotary models enables greater output per unit time. |

Granule Characteristics | Moderate strength, uniform particle size | Harder granules, higher density, very uniform size | Centrifugal force in rotary models ensures more even material stress, leading to better granule quality. |

Suitable Materials | Most general-purpose materials | Materials with slightly higher viscosity or requiring harder granules | Rotary models’ stronger force handles more challenging materials. |

Equipment Structure | Relatively simple | Slightly more complex | Rotary models require higher standards for dynamic balance and structural strength due to high-speed motion. |

Operation & Cleaning | Extremely simple; easy to disassemble and clean | Relatively simple, but slightly more complex structure | Both are easy to clean, but oscillating models excel due to their simplicity. |

Main Application Scenarios | Lab R&D, small-scale trials, multi-variety small-batch production | Small-to-medium batch production; scenarios requiring high granule uniformity | Oscillating models prioritize "flexibility"; rotary models prioritize "efficiency and quality." |

I. Differences in Working Principles and Structures

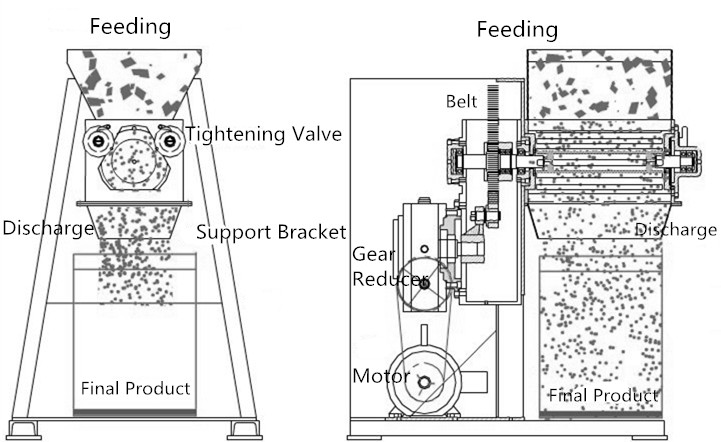

1. Oscillating Granulator

Internal Mechanism: Equipped with a rotor, driven by a crankshaft to perform reciprocating oscillating motion.

Working Process: Functions like a small "roller mill"—scrapes materials upward from the bottom of the screen and extrudes them through the screen holes (from bottom to top).

Structural Features: Simple design, large motion amplitude, but relatively slow speed. No high-speed rotating parts, so requirements for structural stability are lower.

Video Link:

https://youtu.be/gc6S8oOsleo?si=nkNjZss3qyKTkkfT

https://youtu.be/zyh-tvC7BE0?si=pSX49VGNDHpuAUTT

https://youtu.be/_5W9cDnXH6A?si=Jj_BICXP5Xv0rVpp

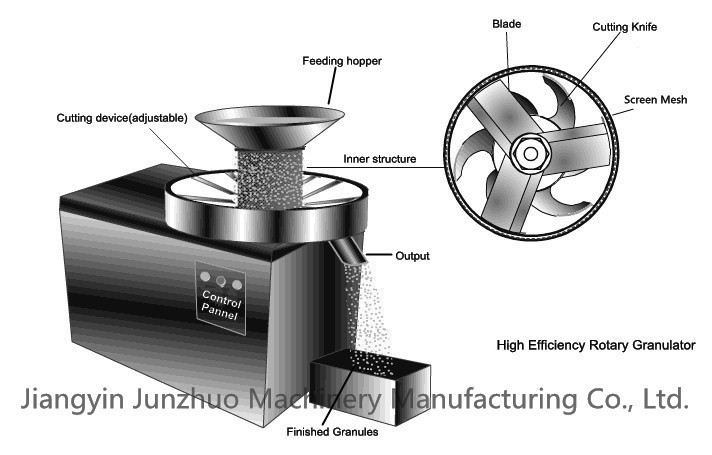

2. Rotary Granulator

Internal Mechanism: Contains a blade and rotary knife, directly driven by a motor for high-speed continuous rotation.

Working Process: Uses centrifugal force to fling materials toward the surrounding screen wall; simultaneously, impellers and granulating blades roll and shear the materials, forcing them through the screen holes (from inside to outside).

Structural Features: More compact design, high motion speed, and stronger force. Requires precision machining to ensure dynamic balance (to avoid vibration during high-speed rotation) and higher structural strength (to withstand centrifugal force).

Video Link:

https://youtu.be/CezFhnFg29I?si=PthhA9d8Yyfwz99_

https://youtu.be/HuFmDjWpyXQ?si=4kp2ZdZagh90IOL8

https://youtu.be/4p3WUC5-rQ8?si=UL54c6TtQ1sE116f

II. Differences in Performance and Output

1. Production Efficiency

Due to its continuous and high-speed working mode, the rotary granulator has a significantly higher production efficiency than the oscillating granulator and is more suitable for occasions with certain output requirements.

2. Granule Quality

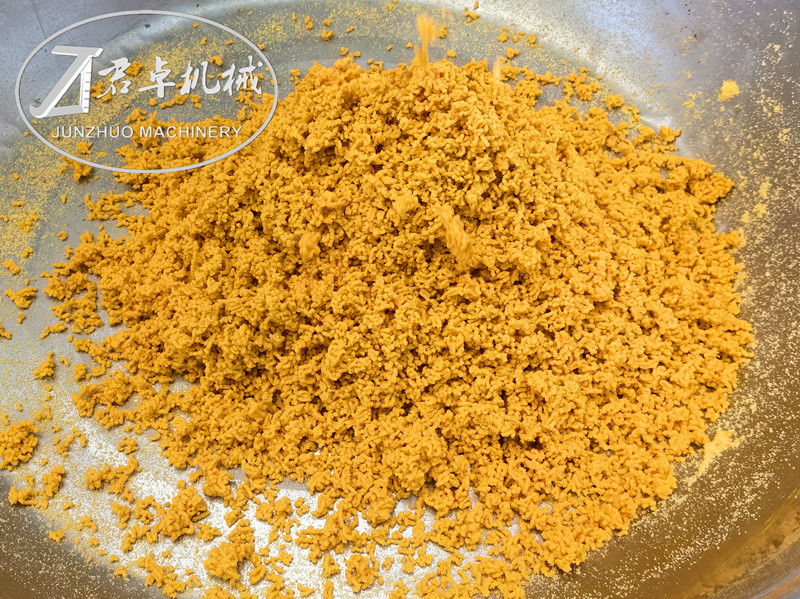

Oscillating Granulator: Granules have moderate hardness and uniform particle size, but density is relatively low (due to intermittent extrusion). They are prone to slight deformation if pressed too hard, which is sufficient for general R&D or low-demand production.

Rotary Granulator: Centrifugal force ensures even material stress during extrusion, resulting in harder, denser granules with a more concentrated particle size distribution. These granules have better mechanical stability (e.g., less breakage during transportation) and are ideal for products requiring high granule quality.

III. How to Choose Between the Two?

The selection depends on your production scale, material properties, and quality requirements:

Scenario | Recommended Granulator | Reason |

Lab R&D, formula trials, frequent material changes | Oscillating Granulator | Simple operation, easy disassembly/cleaning, and low cost—ideal for testing multiple formulas. |

Multi-variety, small-batch production (e.g., small TCM factories) | Oscillating Granulator | Flexibility to adapt to diverse materials; no need for high efficiency. |

Small-to-medium batch production with stable demand | Rotary Granulator | Higher efficiency reduces production time; better granule quality ensures product consistency. |

Processing materials with slightly higher viscosity (e.g., wet TCM extracts) | Rotary Granulator | Stronger centrifugal + extrusion force avoids screen clogging and ensures smooth granulation. |

Products requiring high granule hardness/density (e.g., pharmaceutical tablets, high-end instant drinks) | Rotary Granulator | Denser granules improve subsequent processes (e.g., tableting, dissolution) and product stability. |

Summary

Both oscillating and rotary granulators are mature, high-performance devices—there is no absolute "superiority," only "fit" for specific process needs:

Oscillating granulators are the "flexible all-rounders" for R&D and small-batch production, prioritizing ease of use and adaptability.

Rotary granulators are the "efficient quality experts" for small-to-medium batch production, excelling in output and granule performance.

For many enterprises, a common configuration is to use oscillating granulators in labs (for formula development) and rotary granulators in production workshops (for scaled-up manufacturing)—this combination balances R&D flexibility and production efficiency.

By continuing to use the site you agree to our privacy policy Terms and Conditions.