Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

Screen Sieves for JUNZHUO Oscillating Granulator

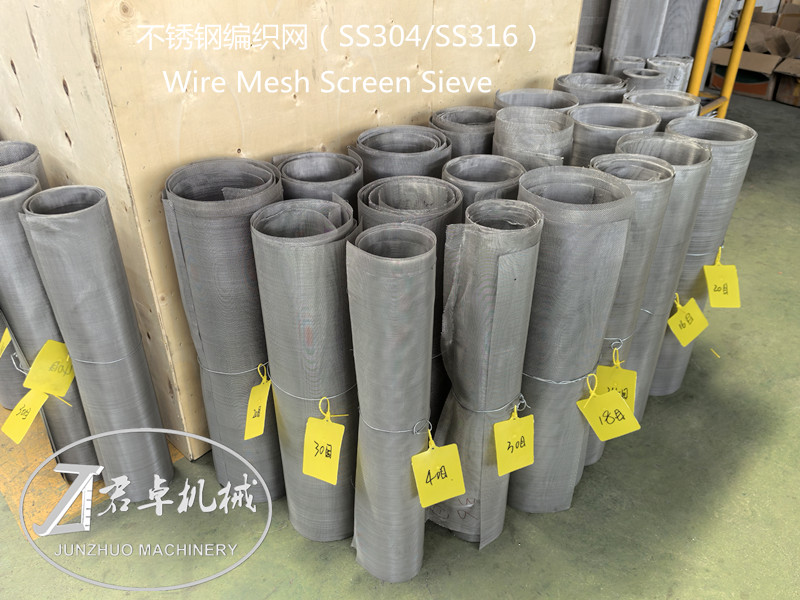

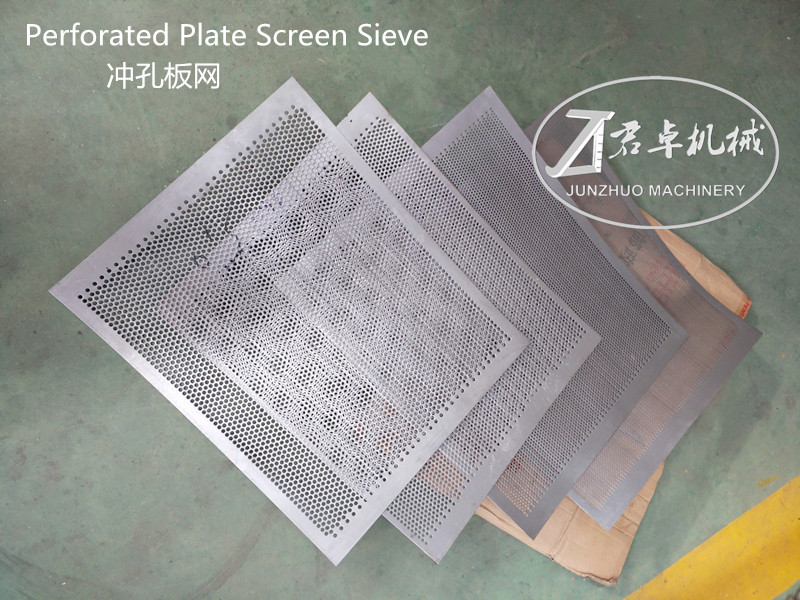

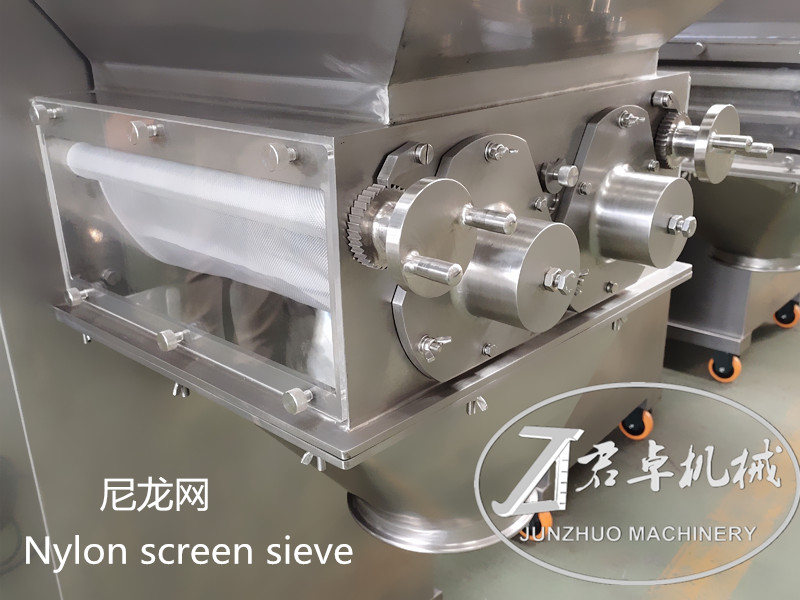

The screen sieve of an oscillating granulator is a critical consumable and working component—it directly determines the size, shape, and output of the final granules. Typically, perforated screen sieves are used for dry materials, while stainless steel wire mesh screen sieves are used for wet materials. JUNZHUO MACHINERY provides all kinds of screen sieves for you, it can be sold by piece, meters or rolls.

I. Core Functions of the Screen Sieve

Molding "Mold"

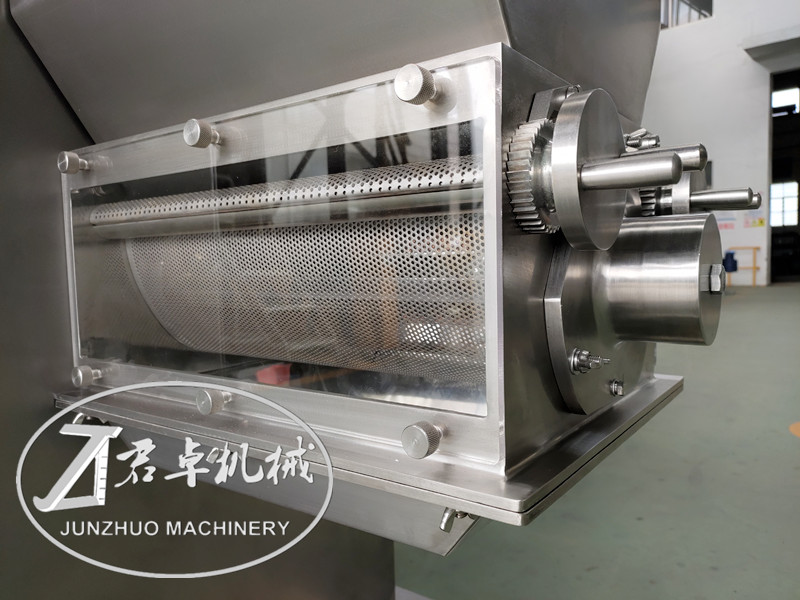

The holes in the screen sieve serve as the exit for materials. Under the extrusion of the rotor, wet soft materials pass through these holes and are cut into cylindrical granules. The screen sieve’s aperture directly defines the diameter of the granules.

Support Role

It provides a reaction force for the rotor’s extrusion, ensuring the smooth progression of the granulation process. Without a stable screen sieve, the rotor cannot apply uniform pressure to form regular granules.

Output Determinant

The total effective filtering area of the screen sieve directly affects output. A larger effective area allows more material to pass through per unit time, increasing production efficiency.

II. Key Parameters of Screen Sieves

1. Material

The material of the screen sieve determines its durability, corrosion resistance, and compliance with hygiene standards—critical for meeting industry regulations (e.g., GMP for pharmaceuticals).

Material Type | Characteristics | Application Scenarios |

304 Stainless Steel | Good corrosion resistance, moderate hardness, cost-effective. | General food, chemical, and non-corrosive pharmaceutical production. |

316L Stainless Steel | Superior corrosion resistance (resists acids/alkalis), low carbon content (avoids intergranular corrosion), fully GMP-compliant. | Pharmaceutical industry (especially for corrosive materials), high-end food production. |

Nylon | Lightweight, non-metallic (avoids metal contamination), good flexibility. | Scenarios where metal impurities are strictly prohibited (e.g., some electronic materials, special food additives). |

Wire mesh screen sieve

Perforated Plate Screen Sieve

Nylon Screen Sieve

2. Aperture / Mesh Size

This is the most critical parameter for screen sieve selection, as it directly controls the particle size of the final product.

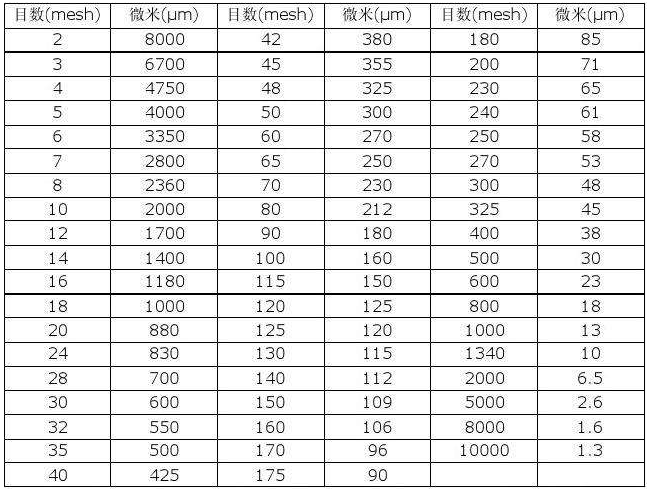

Mesh Size: Refers to the number of holes per inch (25.4 mm) along the length. A higher mesh number means smaller holes and finer granules.

Aperture: The actual diameter of a single hole, usually measured in millimeters (mm) or micrometers (μm). Perforated plate screen sieve according to aperture, its mesh size is different from wire mesh screen sieve, it should be ask for manufacturer.

Common Mesh Size & Aperture Reference Table for Oscillating Granulators

Mesh Size | Approximate Aperture (mm) | Suitable Granule Size | Typical Applications |

10 Mesh | 2.00 | Very coarse granules | Chemicals, animal feed |

14 Mesh | 1.40 | Coarse granules | Primary pharmaceuticals, industrial additives |

16 Mesh | 1.18 | Medium granules | Most common for tablets |

18 Mesh | 1.00 | Medium-fine granules | Tablets, capsules |

20 Mesh | 0.88 | Fine granules | Capsules, fine powder products |

24 Mesh | 0.83 | Very fine granules | Special requirements |

Note: Apertures may vary slightly between different standards. Always confirm the actual aperture (in mm) with the supplier before purchasing.

3. Weaving Method (for wire mesh screen sieve)

Plain Weave: The most common method, where warp and weft wires intersect alternately. It produces square holes, high structural strength, and uniform hole distribution—ideal for most wet granulation scenarios.

4. Wire Diameter (for wire mesh screen sieve)

Refers to the diameter of the metal wire used to make the screen. It balances durability and output:

Thicker Wire: More wear-resistant, longer service life, but reduces the effective filtering area (lower output).

Thinner Wire: Larger effective area (higher output) but less durable, prone to deformation or breakage when processing hard materials.

5. Size & Shape

Oscillating granulator screens are typically rectangular. To ensure proper installation:

Measure the flat length and width of the screen (do not measure curved or folded screen sieves).

For perforated screens: Reserve 10–30 mm of edge (non-perforated area) for fixing to the equipment.

For woven screens (stainless steel/nylon): Add 80–100 mm to the length to accommodate clamping and tensioning.

III. Screen Selection, Use & Maintenance

How to Select the Right Screen?

Based on Process Requirements

Start with the target particle size: For example, if you need granules for tablets, choose 16–18 mesh (1.00–1.18 mm aperture); for capsules, 18–20 mesh (0.88–1.00 mm aperture).

Based on Material Properties

Abrasive Materials: Select thicker wire or perforated screens to avoid rapid wear.

Highly Viscous Materials: Choose smooth-surfaced screens to prevent material adhesion and clogging.

Corrosive Materials: Must use 316L stainless steel or nylon screens.

3. Based on Equipment Model

Confirm the screen size matches your granulator model (e.g., an YK-160 type oscillating granulator typically uses a 500×408 mm screen sieve). An ill-fitting screen will cause material leakage or equipment jamming.

Usage Precautions

1. Proper Installation

Ensure the screen sieve is flat and taut when installed; avoid wrinkles or slack.

Tighten the clamping device firmly to prevent the screen sieve from shifting or rotating during roller oscillation.

2. Adjust Roller-Screen Gap

The ideal gap between the roller and screen is 1–3 mm:

Too Small: Causes severe friction between the roller and screen, accelerating screen wear and generating excessive heat (risky for heat-sensitive materials).

Too Large: Reduces extrusion force, leading to loose granules, excessive fine powder, or uneven particle size.

3. Uniform Feeding

Avoid overloading the hopper with material, especially dry, hard lumps—this causes localized pressure on the screen, leading to deformation or breakage.

Use a feeder (if available) for continuous, uniform feeding.

Common Issues & Solutions

Common Issue | Causes | Solutions |

Difficult discharge, low output | Screen holes clogged by wet/viscous material; effective area reduced. | Stop the machine immediately, remove the screen, and clean with warm water or a suitable solvent (e.g., ethanol for pharmaceutical residues). Use a soft brush to clear stubborn clogs (avoid metal brushes that scratch the screen). |

Incomplete granules, excessive fine powder | 1. Wet material is too dry; 2. Screen is broken (unfiltered powder passes through). | 1. Adjust the material’s moisture content (aim for "forms a ball when squeezed, disperses when touched"); 2. Inspect the screen for holes or tears—replace if damaged. |

Rapid screen wear | 1. Roller-screen gap too small; 2. Material is highly abrasive; 3. Wire diameter too thin. | 1. Increase the gap to 2–3 mm; 2. Replace with a thicker wire or perforated screen; 3. For extremely hard materials, use wear-resistant alloy screens. |

Cleaning & Maintenance

1.Timely Cleaning

Clean the screen immediately after each use—dried material is hard to remove and will clog holes over time.

For water-soluble residues: Rinse with warm water, then dry with compressed air.

For oil-based or sticky residues: Soak in a neutral detergent solution (50–60°C) for 10–15 minutes, then brush gently.

2. Regular Inspection

Check the screen for wear, deformation, or breakage before each use. Slightly worn screens can be flipped (if both sides are usable) to extend service life.

Replace screens if: ① Holes are enlarged by >20% of the original aperture; ② There are visible tears or deformation.

3. Proper Storage

After cleaning and drying, store screen sieves vertically (using a hanging rack) or lay them flat—avoid stacking heavy objects on top (prevents deformation).

Store nylon screens in a cool, dry place to avoid aging from UV exposure.

Summary

The screen sieve is the "heart" of the oscillating granulator. Correct selection, use, and maintenance of the screen sieves are key to ensuring stable granulation processes, uniform particle quality, and high production efficiency. It is recommended to keep a safety stock of screen sieves in commonly used apertures to adapt to changing production needs and avoid downtime due to screen shortages. Any question please contact with us by email jz@junzhuojx.com, we can provides customized design and all spare parts for you.

By continuing to use the site you agree to our privacy policy Terms and Conditions.