Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

The rotary granulator is a common wet granulation equipment used in laboratories and small-scale production. Its working principle is similar to oscillating granulator, but it different from structure and movement mode.

I. Working Principle

The working principle of the rotary granulator is "centrifugal extrusion", which proceeds in the following steps:

Feeding: The wet material (soft mass) is put into a conical or cylindrical screen sieve.

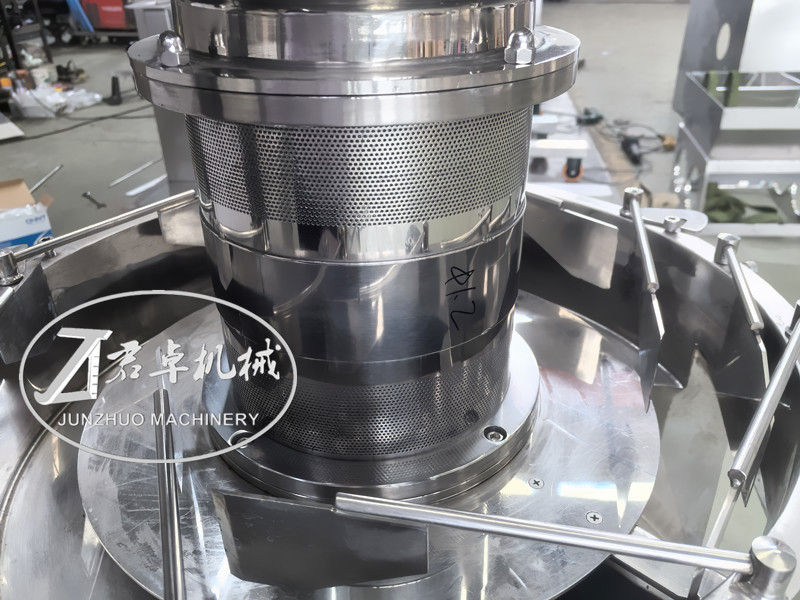

Rotary Extrusion: When the machine is started, the internal blade and granulating knife begin to rotate at high speed.

Centrifugation and Rolling: Driven by centrifugal force, the rotating blade and knife fling the wet material toward the surrounding screen wall, press it tightly against the wall, and simultaneously perform continuous scraping and rolling.

Forced Screening: Under the extrusion and shearing action of the granulating knife, the wet material is forced through the small holes on the screen sieve.

Strip Cutting into Granules: After being extruded through the screen sieve, the material forms cylindrical granule strips, which are immediately cut into short granules and fall into a receiving container.

Video Link:

https://youtu.be/VWITBFupGEA?si=Hl-xP4rzvRZqYNng

https://youtu.be/5xMJMCbgYYI?si=wPR0qh9rblRON0hm

II. Main Features and Advantages

High Granulation Efficiency: Due to the use of high-speed rotating rollers, the centrifugal force generated is large and the extrusion force is strong. As a result, the granulation speed is fast, and the efficiency is higher than oscillating granulator.

High Granule Uniformity: The strong centrifugal force ensures that the material is stressed more evenly. The produced granules have a more concentrated particle size distribution and better uniformity.

Suitability for Viscous Materials: Its strong extrusion force can deal with soft materials with slightly higher viscosity effectively.

Easy Disassembly, Assembly and Cleaning: The screen drum is removed easily, facilitating the replacement of screens with different apertures and thorough cleaning.

Compact Structure: It occupies a small floor area, it is suitable for laboratories and small-scale production workshops.

By continuing to use the site you agree to our privacy policy Terms and Conditions.