Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

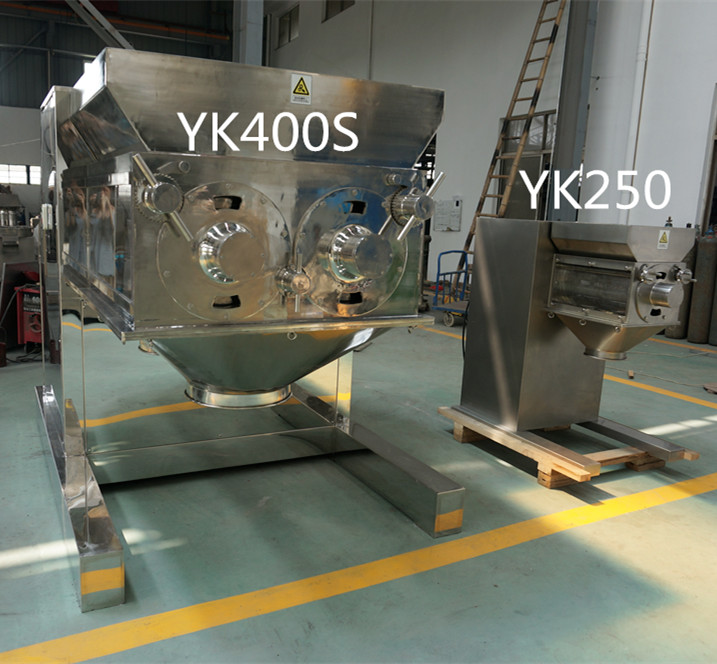

Double Rotor Oscillating Granulator

I. Concept

The double rotor oscillating granulator is a typical representative of the development of oscillating granulation technology toward higher efficiency and larger scale. Derived from the classic single rotor oscillating granulator, this high-performance model is mainly designed to significantly improve production efficiency and meet the requirements of larger-batch production. It retains the working principle and all advantages of the single rotor model while achieving a leap in production capacity through structural innovation.

It keeps the advantages of the oscillating granulation technology—such as high-quality granules, wide applicability, and simple operation—it solved the problem of production capacity through the parallel design of two working units. It is an ideal choice for many enterprises to upgrade their production capacity.

II. Main Features and Advantages (Compared with Single rotor Oscillating Granulators)

Core Advantage: High Efficiency and High Output

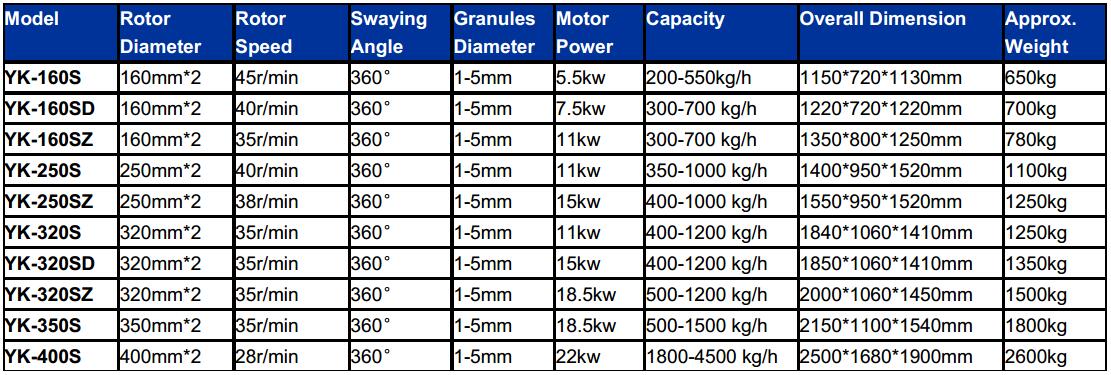

This is its most prominent feature. At the same time, its output is nearly twice of a single rotor model, so that it is very suitable to pilot-scale amplification and large-scale production, and effectively shortening the production cycle.

Excellent Investment Cost-Effectiveness, Energy Saving, and Space Saving

One Machine Equals Two: It achieves double production capacity, but its cost is lower than two independent single rotor granulators.

Energy Saving: It has one set of drive system and control system, which is more energy-efficient than operating two independent single rotor oscillating granulators.

Space Saving: The floor space occupied by one double rotor oscillating granulator is much smaller than two single rotor oscillating granulators, the workshop layout is optimized.

Maintaining Consistency in Granule Quality

It may have slight mechanical differences with two single rotor oscillating granulators purchased from the same manufacturer, which will cause minor variations in granule tightness and particle size distribution. However, the granules produced by a double rotor oscillating granulator have highly uniform quality, it can meet the GMP requirements for in-batch uniformity.

Simple Operation and Reduced Human Error

Unified Control: Only one control panel needs to be operated (e.g., setting rotation speed), avoiding parameter setting errors that may occur when operating two machines separately.

Centralized Management: Maintenance, cleaning, and record-keeping only need to be performed for one set of equipment, improving management efficiency.

III. Main Application Scenarios

The double rotor oscillating granulator is not used for initial formula exploration in laboratories; instead, it focuses on production at more advanced stages:

Pilot Plant:

It is used for scale-up trial production of formulas successfully developed in laboratories, providing process parameters and data support for final large-scale production.

Commercial Production of Multiple Varieties in Small-to-Medium Batches:

It is suitable for scenarios where the production demand exceeds the capacity of a single rotor model but does not require investing in a large-scale continuous granulation line. It is commonly used in small-to-medium-sized pharmaceutical factories, food factories, and chemical plants.

Large-Batch Production of Core Formulas:

When the demand for a specific product is very high, the double rotor oscillating granulator can efficiently complete the granulation process.

By continuing to use the site you agree to our privacy policy Terms and Conditions.