Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

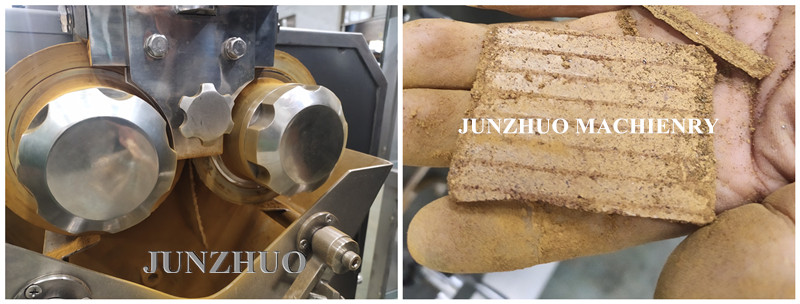

This showed our GK-60 model testing dry powder into 25-60 mesh size. The smaller of the granule size, the capacity will be less. Output granules need be sifted.

Video Link:https://youtu.be/RksYgzWQNqU?si=ZCFBwvOaTCPxpSeJ

Main Application:

In pharmaceutical industry, roller compaction has become the method of choice for dry granulation.

Because of its reasonable design, the process technology can be almost completely disassembled without special tools.

The movable design provides great flexibility during compaction feasibility studies and allows an easy maintenance.

Working Principle:

1. Material is fed between two counter-rotating roll presses.

2. The rolls apply extreme pressure, to press the material into a sheet form.

3. This sheet of material is then fed through a granulator, where it is broken up into uniformly sized granules.

4. Output is depended upon the mesh size and material density. Output granule size depends on screen sieve hole size.

Technical Data:

1.Capacity: 20-100kg/h(Output of Sheet)

5-40kg/h(Output of Granule)

2. Output size: 0.5-3 mm

3.Feed Screw Speed: 6-65 RPM(Frequency control)

4.Roller Speed: 4-25 RPM (Frequency control)

5. Granulating motor power: 0.75KW(Frequency control)

6. Feeding motor power: 0.55KW

7. Tableting motor power: 3KW

8. Side Seal Pressure: 9.8KN

9. Max. Pressure: 294KN

10.Overall Diameter: 1085*650*1600mm

11. Approx. Weight: 750KG

By continuing to use the site you agree to our privacy policy Terms and Conditions.