Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

This refers to the installation form of the equipment. It is usually a relatively compact and complete independent unit that can be directly placed on a workbench, platform, or bracket for use. It does not require complex fixed installation or a large foundation.

I. Main Features

Compact Size: It has a lightweight design and a small footprint, which maximizes the saving of valuable space in laboratories or small workshops.

Flexible Mobility: It is usually equipped with casters or a structure for easy handling, allowing it to be easily moved between different workstations for shared use.

Simple Operation: The control system is usually directly integrated into the machine, with button operation that is simple, intuitive, and easy to learn and use.

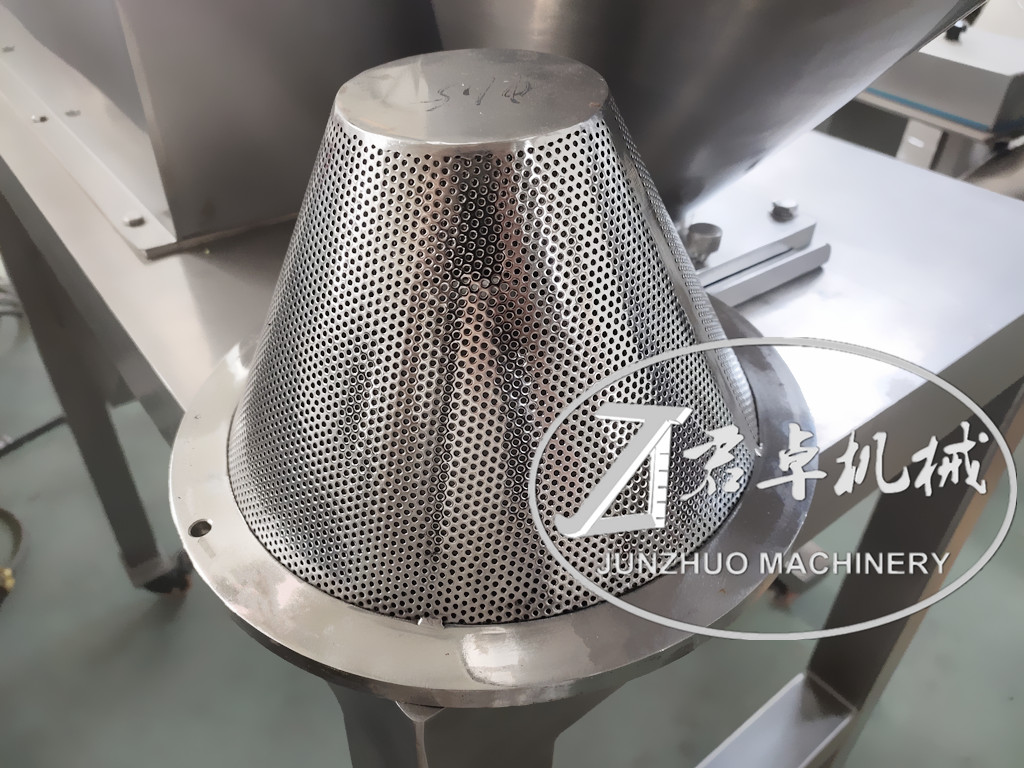

Easy to Clean: Similar to large-scale equipment, the parts that come into contact with materials (such as the hopper, blades, and screen) can be quickly disassembled, facilitating thorough cleaning and material changeover to prevent cross-contamination.

Undiminished Functionality: Despite its small size, its working principle (high-speed shearing, extrusion screening) and core functions are completely consistent with those of large-scale production-type rapid granulators, and it can produce granules of the same high quality.

Cost-Effective: Its price is much lower than that of large-scale production equipment, making it an ideal choice for process exploration, formula research and development, small-batch trial production, or teaching demonstrations.

II. Typical Applications

1 .Pharmaceutical and Laboratory Research & Development (R&D)

Process Development: During the development stage of new drugs or new formulas, it is used to determine the optimal granulation process parameters (such as screen aperture, blade speed, etc.).

Small-Batch Trial Production: Used to produce materials required for clinical trials (Phase I, Phase II).

Universities and Research Institutes: Used for teaching and student experiments to demonstrate the process of wet granulation or dry granulation.

2. Food and Cosmetics R&D

Used to develop new food formulas (such as solid drinks, seasonings) or cosmetic formulas (such as pressed powders, bath bombs), and conduct small-batch granulation tests.

3. Small-Scale Specialized Production

For some specialty chemicals, high-end ceramic powders, or special products with low demand, table-top equipment can meet all their production needs.

III. Purchase Considerations

1. Production Capacity: The capacity of table-top granulators is usually small (e.g., a few kilograms to more than ten kilograms per hour), so you need to choose according to your specific needs.

2. Material: It is essential to ensure that the parts in contact with materials are made of 316L stainless steel to guarantee corrosion resistance and compliance with hygiene standards.

3. Screen Configuration: Inquire with the supplier whether screens of multiple apertures (e.g., 0.5mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, etc.) are provided to meet different experimental requirements.

4. Brand and Support: Choose a supplier that provides good technical support and spare parts services.

By continuing to use the site you agree to our privacy policy Terms and Conditions.