jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

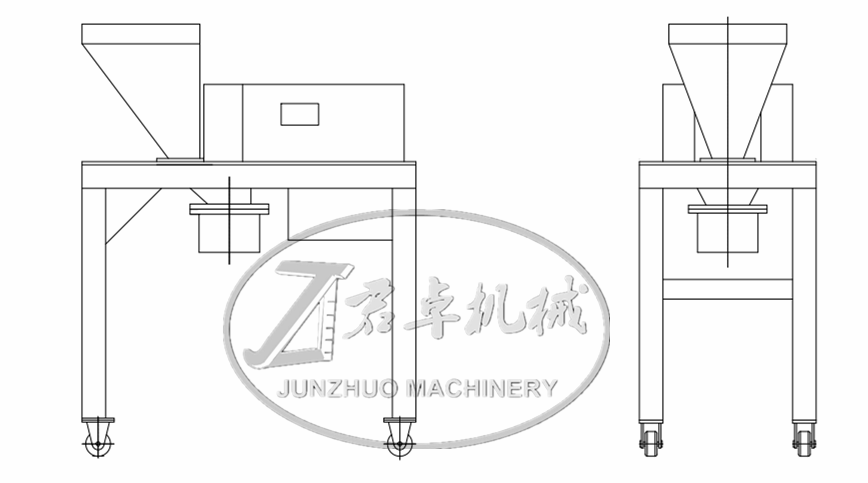

This FZL80 model cone mill is the smallest model, it is suitable for lab use. The machine is a table type, it is moveable. It is recognized as one of the most versatile size reduction machines in the pharmaceutical industry.

Cone Mill--Solid Particle Size Reduction Equipment

Cone Mill, we called it conical mill, high speed granulator, fast granulator, quick granulator and grinding granulator. It is recognized as one of the most versatile size reduction machines in the pharmaceutical industry. Its ability to take a relatively wide size range of feed material and produce a similarly wide range of product, makes it ideal for intermediate sizing in both wet and dry granulations processes.

Our comprehensive range includes a variety of model types including top driven and under-driven, as well as the option of belt and direct drive.

By changing a combination of screen, impeller shape and speed, the finished milled particle size can be carefully controlled.

Application:

Dry & Raw Material Milling & Grinding

Dry & Wet Granulation Sizing.

Tablet & Capsule Reclaim.

Dry Mixing Dispersion.

Deagglomeration

Wet Material Size Reduction.

型号Model | 旋簧长度 (mm) Cone Knife Length | 滤孔直径 (mm) Screen Sieve Diameter | 生产能力(kg/h)Capacity | 电机功率 (KW) Motor Power

| 转速Rotation Speed | 外型尺寸 (mm)Overall Size | 重量(kg) Approx. Weight |

FZL80 | 55 | 1-8 | 20-50 | 0.55 | 单速2800或变频调速300-3000 Normal 2800 r/min or Frequency 300-3000 r/min | 780×280×750 | 50 |

FZL120 | 80 | 1-8 | 100-300 | 1.1 | 变频调速200-1450或400-3000 Frequency 200-1450r/min or 400-3000r/min | 850×450×1100 | 150 |

FZL160 | 120 | 1-8 | 100-450 | 1.5 | 900×500×1480 | 180 | |

FZL180 | 135 | 1-8 | 100-550 | 1.5-2 | 1000×520×1480 | 200 | |

FZL200 | 140 | 1-8 | 200-700 | 2.2-3 | 1250×500×1450 | 250 | |

FZL250 | 200 | 1-8 | 400-1500 | 4 | 1200×700×1450 | 250 | |

FZL300 | 220 | 1-8 | 450-2500 | 5.5 | 1200×700×1450 | 270 | |

FZL350 | 240 | 1-8 | 500-3500 | 7.5 | 1350×750×1500 | 450 |

Top-driven type

| Model | KZL-80 | KZL-120 | KZL-160 | KZL-180 | KZL-200 |

| Capacity | 20-50kg/h | 100-200kg/h | 100-300kg/h | 100-400kg/h | 200-500kg/h |

| Spring Length | 55mm | 80mm | 120mm | 135mm | 140mm |

| Screen Sieve Size | 1-8mm | 1-8mm | 1-8mm | 1-8mm | 1-8mm |

| Motor Power | 0.55kw | 1.1kw | 1.5kw | 1.5-2kw | 2.2-3kw |

| Rotation Speed | 2800 r/min or Frequency 300-3600 r/min | Frequency 200-1500r/min or 400-3000r/min | |||

| Overall Dimension | 780*280*750mm | 850*450*1100mm | 900*500*1480mm | 1000*520*1480mm | 1250*500*1450mm |

| Approx. Weight | 50kg | 150kg | 180kg | 200kg | 250kg |

The material to be processed enters into the feed inlet of the cone mill, which drops into the conical sieve chamber. The rotary knife rotates against the material, and grinds the granules against the sieve mesh surface. The granules are ground into particles by the shearing action produced by the rotary knife and sieve mesh, and then discharged through the sieve holes. This model is top driven by direct or belt.

JUNZHUO MACHINERY offers all the spare parts, such as the cone blade,impeller,screen sieves with multiple hole sizes and shapes (such as round hole and square hole).

Top-driven Conical mills come in a variety of sizes from tabletop lab models to full-size high-capacity machines for use in processing large quantities of material, and the impeller and screen can be customized for each individual use. The machines can be used not only to reduce the size of particles, but also for deagglomeration, sieving, dispersion, and mixing. |

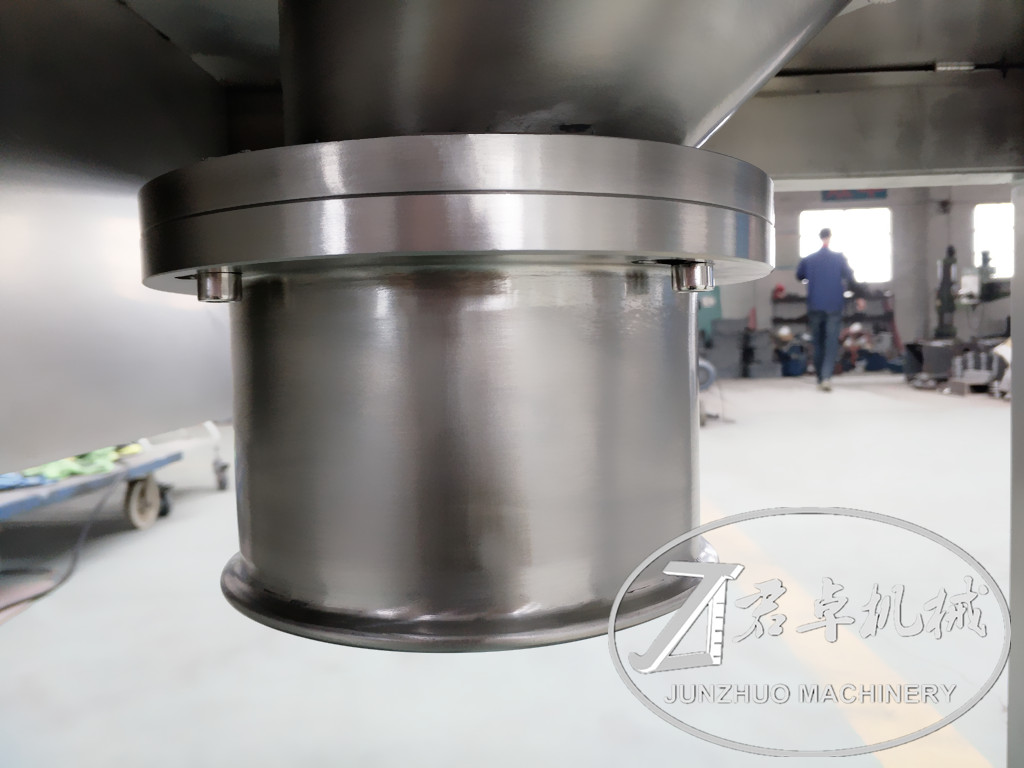

Milling chamber The conical mill operates by having the product being fed into the mill by gravity or vacuum. A rotating impeller forces the material outward to a conical screen surface, where it is sized and passed through the openings in the screen. Once finished, the product simply drops through the milling chamber to a receptacle underneath. |

Rotating impeller The material move into action zone where the centrifugal force generated by anchor impeller throws the material through the screen. |

Screen sieve Shearing effect is depends upon velocity of particle passing through the screen hole. Tooling can be customised including screen hole size, screen hole shape (Round-Hole, Square-Hole, Grater-Hole). |

Variable speed control To achieve consistent particle size and output, need to validate screen hole type, impeller design & RPM. |

Discharge Various systems like drying, milling can be retrofitted with Cone mill & to a downstream process by vacuum transfer. |

By continuing to use the site you agree to our privacy policy Terms and Conditions.