jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

The GHJ series V-type blender is used to produce homogeneous solid-solid mixture. Mixing is a common process step in the manufacture of products for industries such as food, cosmetics, pharmaceutical, chemical, detergents, fertilizers and plastics.

V type mixer

Main Application

V type mixer is suitable for mixing powder and particles with good material fluidity and small physical property difference, as well as the materials with low mixing requirement and short mixing time. It is widely used in pharmaceutical, chemical, food and other industries.

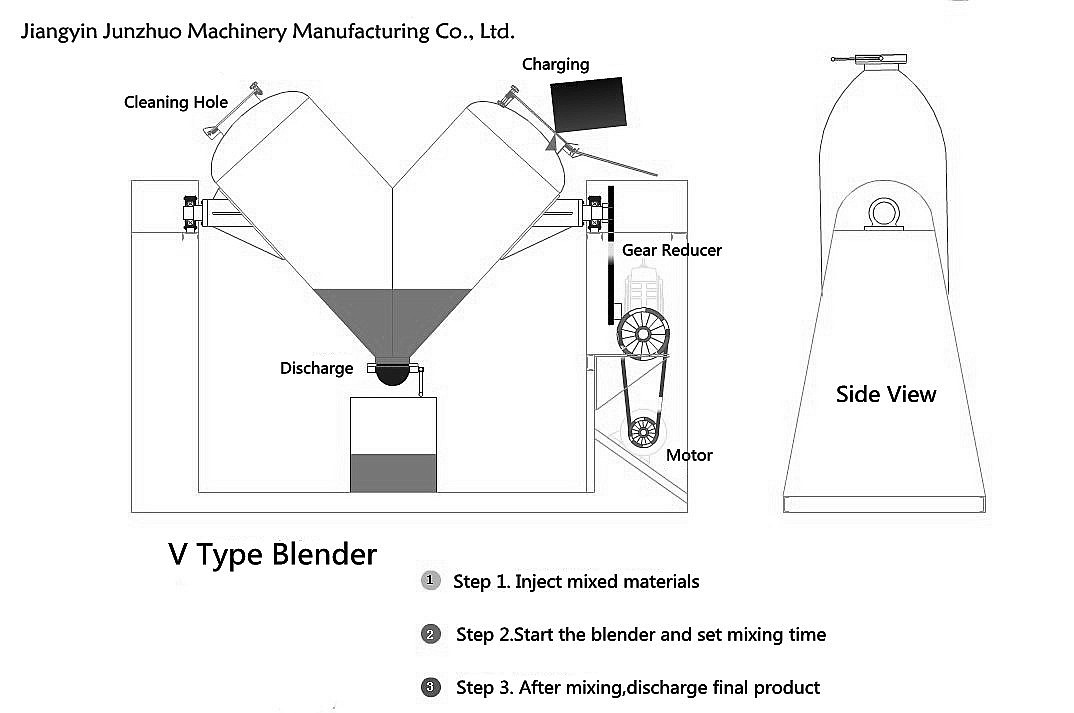

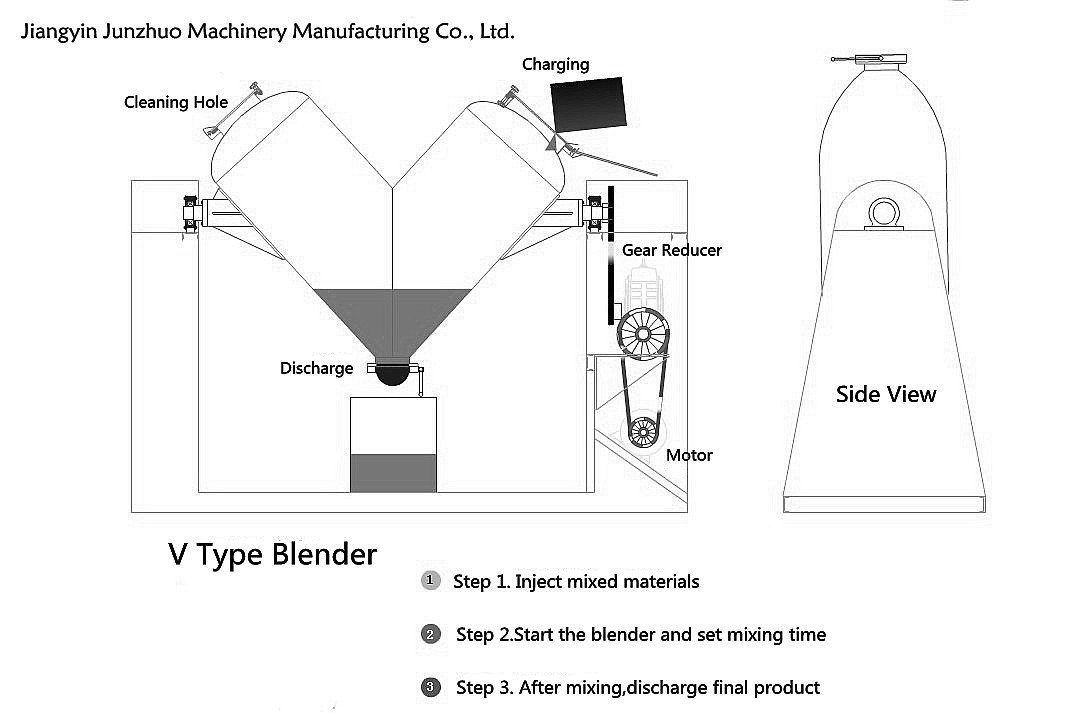

The unit consists of two cylinders arranged in a "V" shape. A manually actuated inspection and loading port is provided at the end of each cylinder, allowing access to its interior. The product outlet is located at the point where the two cylinders are joined and is fitted with a manually or automatically actuated butterfly valve. The geared motor and the bearing system are located within the lateral supports holding the blender body.

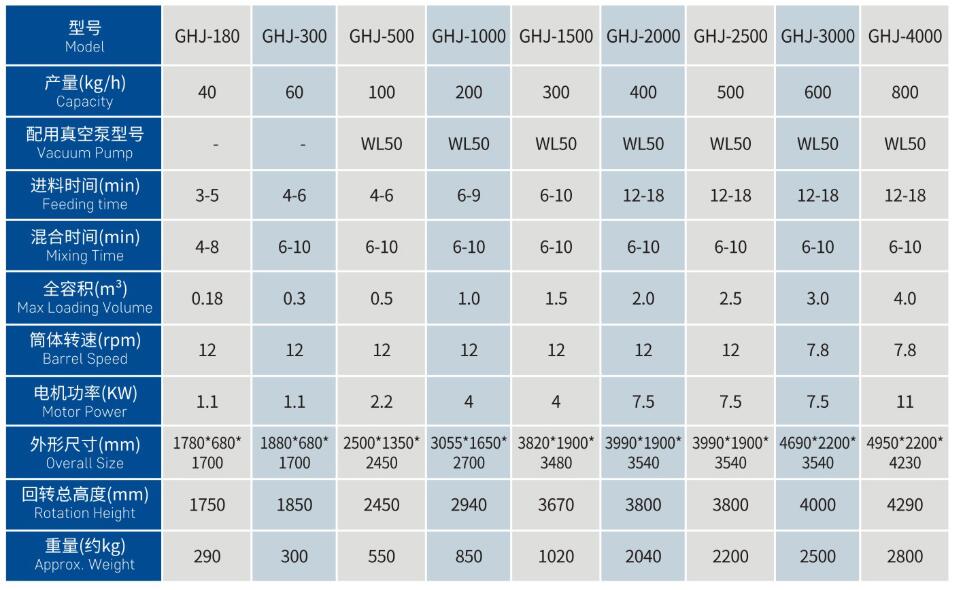

Technical Data

By continuing to use the site you agree to our privacy policy Terms and Conditions.