Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

Solutions to Rapid Screen Wear in Oscillating Granulators

Rapid screen wear is a common and frustrating issue with oscillating granulators. It not only increases production costs but also undermines the stability of granule quality. To resolve this problem, it is essential to systematically identify the root causes and implement targeted measures. Below are the main reasons for rapid screen wear and corresponding solutions:

I. Main Causes & Corresponding Solutions

1. Mechanical Adjustment Issue: Improper Roller-Screen Gap

This is the most common cause of rapid wear. If the gap between the roller (heptagonal roller) and the screen is too small, the roller acts like a grinding wheel—rubbing against the screen at high speed and causing severe abrasion.

Solution:

Re-adjust the Gap: The standard gap should be maintained between 1–3 mm.

Adjustment Method:

1. Shut down the equipment and disconnect the power.

2. Use a feeler gauge to measure the gap at 3–4 evenly spaced points around the roller (ensure uniformity).

3. Fine-tune the gap using the adjustment bolts at both ends of the roller: Turn clockwise to reduce the gap, or counterclockwise to increase it.

4. After adjustment, manually rotate the roller 1–2 full turns to confirm no friction or scraping occurs between the roller and screen.

2. Material Property Issue: Hard or Abrasive Materials

If the material contains high-hardness components or is inherently abrasive, it will act like sandpaper—quickly wearing down the screen’s wire or hole edges.

Solution:

Preprocess the Material: Pre-crush high-hardness raw materials to a finer particle size before granulation. This reduces the "cutting" effect of hard particles on the screen.

Optimize the Formula: Collaborate with the R&D team to evaluate if excipients can be adjusted (e.g., replace part of the abrasive filler with a softer alternative like microcrystalline cellulose) to reduce material abrasiveness.

Choose Abrasion-Resistant Screens: This is the most direct fix (detailed in Section II below).

3. Operational Process Issue: Improper Feeding or Over-Dry Soft Material

Two common operational mistakes accelerate screen wear:

(1) Overloading the Hopper

Adding too much material at once causes excessive pressure on the roller and screen. The increased friction between the compressed material and screen speeds up wear.

(2) Over-Dry Soft Material

Dry, hard soft material requires far more extrusion force to pass through the screen. This extra force increases the friction between the material and screen, leading to rapid wear.

Solution:

Uniform, Moderate Feeding: Follow the "small, frequent batches" principle. Use a feeder (if available) to ensure continuous, even feeding, or manually add material in small portions to keep the hopper 1/3–1/2 full. Avoid letting the hopper run empty (causes dry friction between roller and screen) or overflow (causes overload).

Strictly Control Soft Material Moisture: Ensure the soft material meets the "forms a ball when squeezed, disperses when touched" standard. If the material is too dry:

Increase the amount of binder (e.g., water, ethanol, starch paste) slightly.

Extend the wet mixing time to ensure uniform moisture distribution.

4. Equipment Issue: Deformed Roller or Wobbly Main Shaft

If the roller is not perfectly round or the main shaft bearing is worn, the roller will run unsteadily—causing irregular collision and friction with the screen. This leads to localized rapid wear.

Solution:

Inspect Equipment Precision:

1. Shut down the equipment and remove the screen.

2. Manually rotate the roller slowly and observe if it runs in a perfect circle.

3. Check for main shaft wobble: If the roller "shakes" while rotating, the bearing is likely worn.

Contact After-Sales Maintenance: Do not attempt to repair the roller or replace the bearing yourself. Invite professional technicians to:

Replace worn bearings.

Repair or replace a deformed roller.

II. How to Choose More Durable Screens

If the above adjustments still fail to reduce wear, upgrading the screen itself is critical. Focus on two key parameters:

1. Thicker Wire Diameter

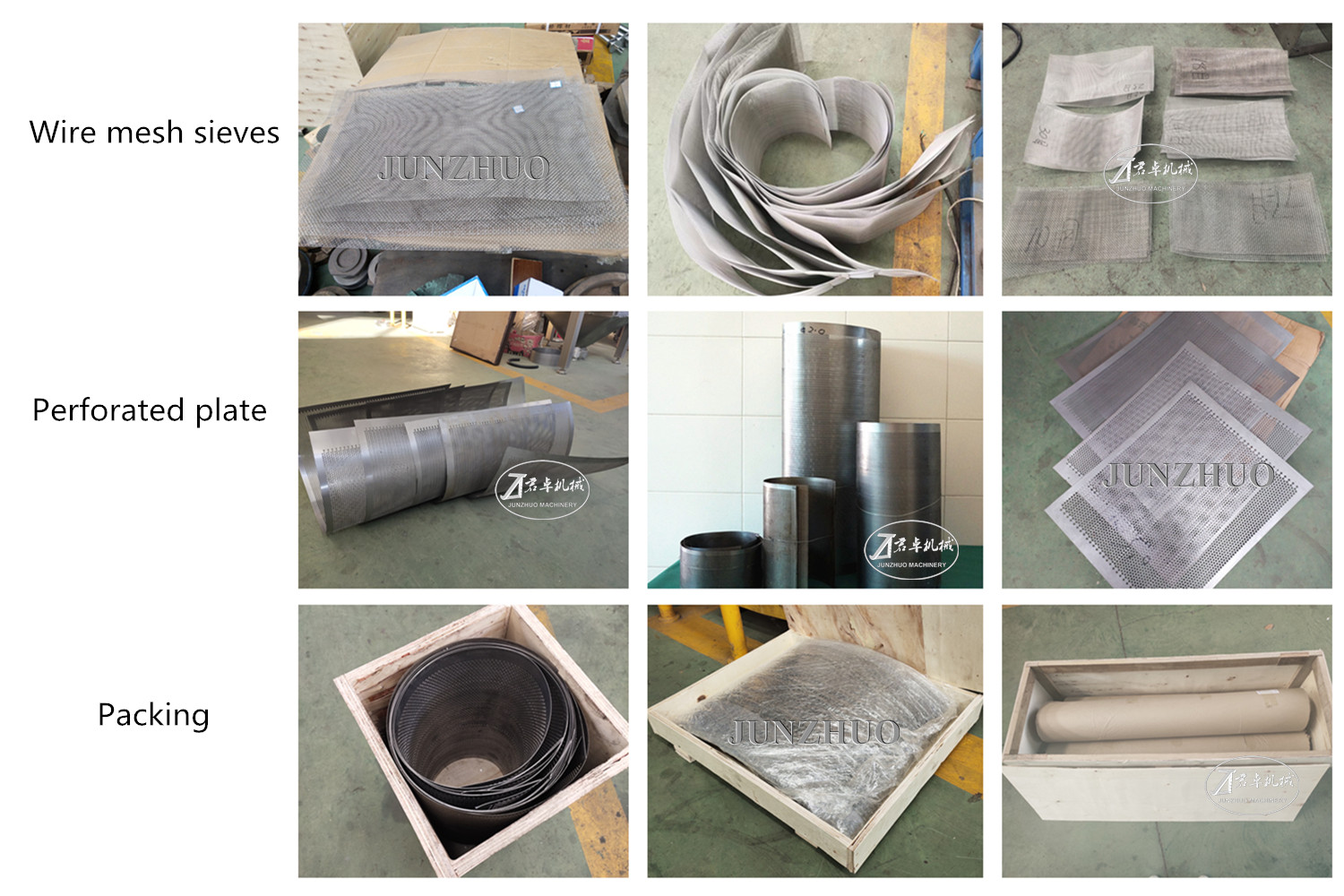

For woven stainless steel screens, increasing the wire diameter directly enhances wear resistance without changing the aperture.

Note: Thicker wire reduces the screen’s effective filtering area, but the extended service life offsets this tradeoff.

2. Wear-Resistant Materials

Base Choice: Ensure the screen is made of 304 or 316L stainless steel (316L is more corrosion-resistant and slightly harder than 304).

Upgraded Options:

Perforated Screens (for Dry Granulation): If processing dry, hard lumps, replace woven screens with perforated stainless steel screens. Perforated screens have higher structural strength and are far more wear-resistant than woven screens.

III. Quick Troubleshooting Checklist for Rapid Screen Wear

When rapid wear occurs, follow this sequence to identify and resolve the issue:

Checklist Order | Inspection Item | Solution |

1 | Is the roller-screen gap within 1–3 mm? | Re-adjust to the standard range (use a feeler gauge for accuracy). |

2 | Is the soft material moisture appropriate? (Forms a ball when squeezed, disperses when touched) | Adjust binder dosage to optimize soft material consistency. |

3 | Is feeding uniform and moderate? | Switch to small, frequent feeding; avoid overloading or empty hoppers. |

4 | Does the material contain high-hardness components? | Pre-crush raw materials or switch to a thicker-wire, abrasion-resistant screen. |

5 | Does the roller run smoothly (no wobble or deformation)? | Contact after-sales to inspect/replace bearings or the roller. |

Core Recommendation

Prevention is better than cure. Extending screen life economically relies on:

Good Operating Habits: Train operators to control soft material moisture, feed evenly, and check the roller-screen gap daily.

Regular Equipment Maintenance: Inspect the roller, main shaft, and bearings monthly; replace worn parts proactively.

Optimize Screen Selection: For fixed formulas, test 2–3 screen types (different wire diameters/materials) to find the one that balances durability and output.

By addressing both operational and equipment factors, you can significantly reduce screen replacement frequency, lower costs, and ensure stable granulation quality.

By continuing to use the site you agree to our privacy policy Terms and Conditions.