Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

How to Select the Suitable Oscillating Granulator?

When choosing an oscillating granulator, clarifying and confirming the following key information is essential.Following this checklist ensures you select equipment that fits your production needs.

Core Checklist for Oscillating Granulator Selection

I. Material Characteristics (Primary Factor)

Understanding your material’s properties is the first and most critical step, as it directly determines whether the equipment can operate smoothly and produce qualified granules.

Material Name & Chemical Properties

Clearly define the material’s chemical nature: Is it corrosive or oxidative? This determines the required material of the equipment’s contact parts.

Physical Properties

Hardness: Is the material soft, brittle, or tough/fibrous? Fibrous materials may require stronger extrusion force.

Viscosity: How viscous is the material? Highly viscous materials are prone to adhering to the rotor and screen, leading to clogging.

Bulk Density: Is it a light powder or heavy powder? Light powders may require adjustments to feeding speed to avoid floating.

Moisture/Oil Content: For wet granulation, what is the moisture range of the soft material? Does the material itself contain oil? Oily materials may affect granule cohesion.

Special Properties

Heat Sensitivity: Is the material sensitive to temperature? Although oscillating granulators generate little heat, prolonged friction may still affect heat-sensitive materials.

Corrosiveness: Do you need special materials for parts in contact with the material? 316L stainless steel has stronger corrosion resistance than 304 and is suitable for acidic/alkaline materials.

Video Link:

II. Process Requirements

Define your production goals to match the equipment’s performance parameters.

Target Output (Capacity)

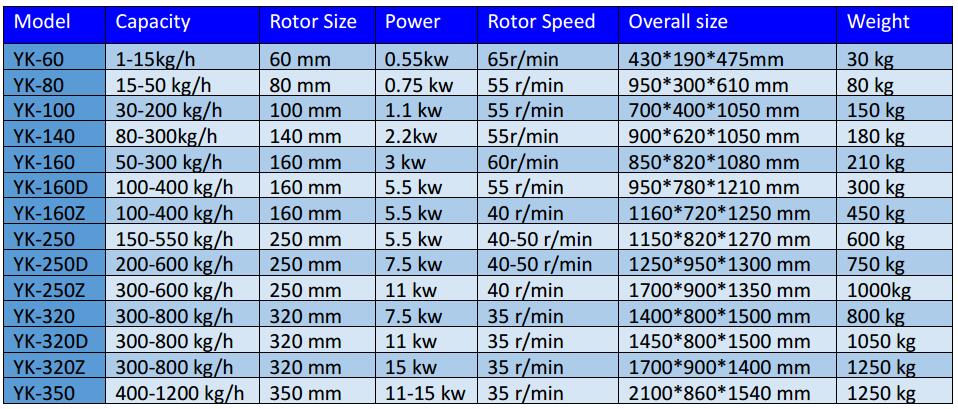

What is the required hourly processing capacity (kg/h)? This is the main basis for determining the equipment model. Overestimating capacity leads to unnecessary costs, while underestimating causes production bottlenecks.

Target Particle Size

What particle size do you need (e.g., 14 mesh, 16 mesh, 20 mesh)? The screen aperture directly determines the final particle size—confirm that the supplier provides screens matching your required mesh size.

Process Type

Will the equipment be used for wet granulation (converting wet soft materials into granules) or dry granulation (crushing dry lumps into granules)? Dry granulation requires higher extrusion force, so the equipment’s roller hardness and motor power need to be verified.

III. Equipment Configuration & Performance

Evaluate the equipment’s structural design and functional parameters to ensure it meets long-term stable operation and process flexibility needs.

Material Requirements

Parts in contact with materials (rotor, screen sieve, hopper) must be made of 304 or 316L stainless steel to comply with GMP (Good Manufacturing Practice) hygiene standards and avoid material contamination. For corrosive materials, prioritize 316L.

Screen Specifications

Aperture Range: Does the supplier offer screens with the aperture you need? Are common apertures (e.g., 0.5–5 mm) readily available for purchase or replacement?

Fixing Method: Is the screen sieve easy to disassemble and install? Quick-release designs save time during screen sieve replacement and cleaning.

Rotor Adjustment

Is the gap between the rotor and screen adjustable? High-quality equipment allows fine adjustment of the gap (usually 1–3 mm). A smaller gap improves granule density, while a larger gap reduces screen wear—adjustments should adapt to different material viscosities.

Drive System

Motor Power & Brand: What is the motor power? Ensure it matches the target output (higher output requires higher power). Opt for well-known brand motors (e.g., Siemens, ABB) for better reliability.

Control Method

Basic Type: Does it have simple on/off switches and stepless speed regulation?

Advanced Control: Is variable-frequency speed control available? This allows precise adjustment of the oscillation speed to optimize granule quality for different materials.

IV. Compliance & Safety

For industries with strict regulatory requirements (e.g., pharmaceuticals, food), compliance and safety are non-negotiable.

GMP Compliance

Is the equipment design easy to clean, with no dead corners? The surface of contact parts should have a smooth finish (Ra ≤ 0.8 μm) to prevent material residue. Avoid complex internal structures that are difficult to clean.

Safety Protection

Does the equipment have necessary safety interlocks? For example, when the protective cover (hopper cover or side cover) is opened, the power should automatically cut off to prevent accidental injury from moving parts.

Explosion-Proof Requirements

If processing materials containing flammable and explosive organic solvents, do you need an explosion-proof motor and explosion-proof control system? Ensure the equipment meets national explosion-proof standards.

V. Operation & Maintenance

Consider long-term usability and maintenance costs to avoid operational inefficiencies.

Cleaning Method

Is cleaning manual (disassembling parts for washing) or does it require complex online cleaning (CIP)? Oscillating granulators typically rely on manual disassembly—prioritize equipment with fewer parts and simple disassembly to reduce cleaning time.

Space & Installation

What are the equipment’s final installation dimensions (length × width × height)? Ensure your workshop has sufficient space for placement and operation.

Do the feeding and discharging heights match your upstream/downstream equipment (e.g., mixer feeding, conveyor discharging)? Mismatched heights may require additional lifting or conveying devices.

Selection Summary & Recommendations

Use the following questions to confirm your needs and communicate with suppliers:

Evaluation Dimension | Questions to Ask Yourself & Suppliers |

Material | Is my material a heat-sensitive TCM extract? Is it tough/fibrous or brittle/crystalline? |

Capacity | What is the maximum hourly material processing requirement? |

Particle Size | What mesh size of granules do I need? |

Equipment | Are the contact parts made of 304/316L stainless steel? Is screen replacement easy? |

Safety | Does it have safety interlocks? Is explosion-proof configuration required? |

Cleaning | Is disassembly and cleaning simple and fast? |

Final Recommendation

Before placing a final order, provide your material samples to the supplier for on-site testing. This is the most direct and reliable way to verify if the equipment is truly suitable for your material.

By continuing to use the site you agree to our privacy policy Terms and Conditions.