Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

I. Applications

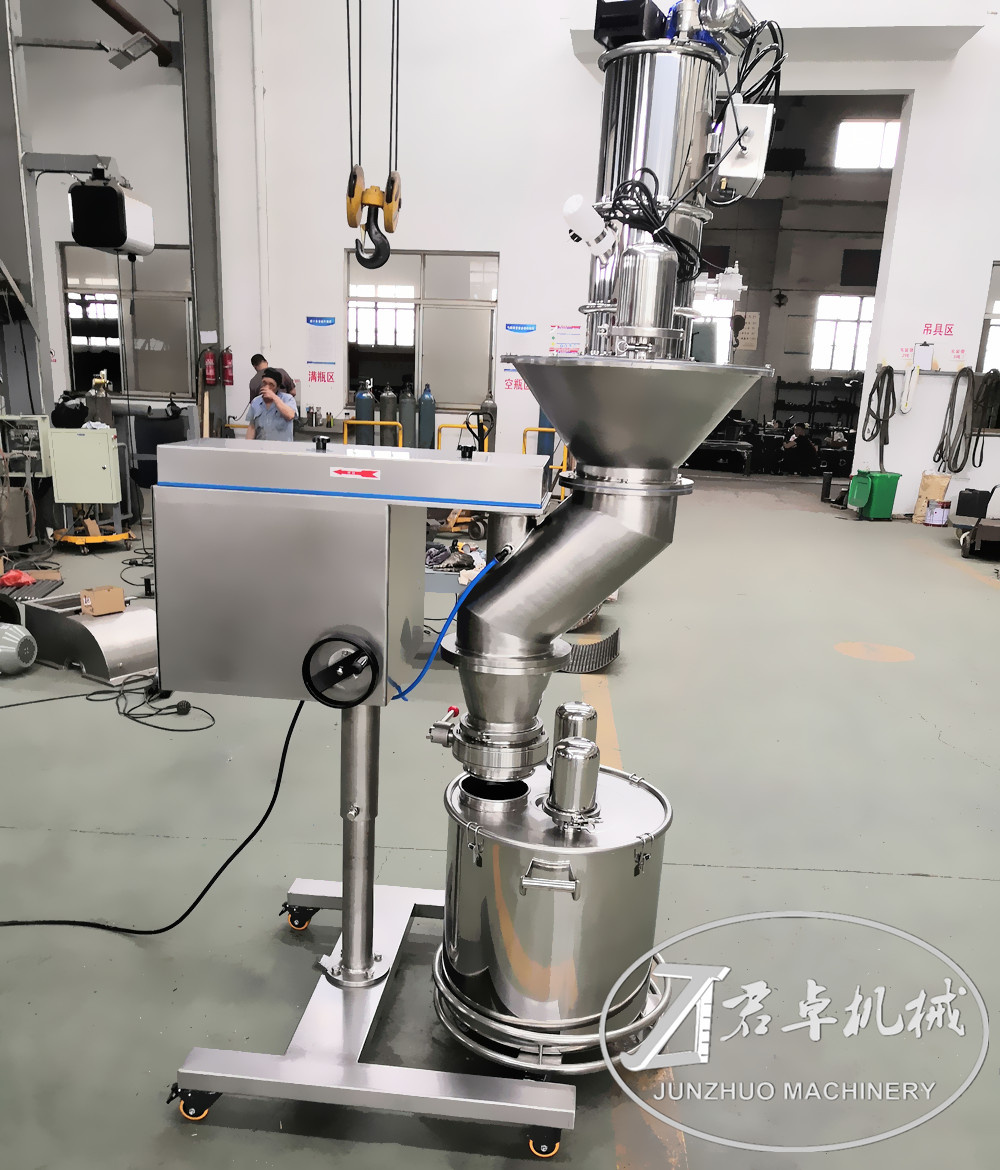

In-Line / Pipeline Type: This means the equipment itself functions as a section of pipeline, with its inlet and outlet featuring standardized pipeline connections (such as flanges and quick-clamp fittings). It is designed to be directly installed in the material conveying pipeline, serving as an integral part of the pipeline system rather than an independent machine unit. It can be connected to upstream and downstream production lines, adopts vacuum conveying, and its discharge port can be linked to material barrels or downstream equipment.

型号Model | 旋簧长度 (mm) Cone Knife Length | 滤孔直径 (mm) Screen Sieve Diameter | 生产能力(kg/h)Capacity | 电机功率 (KW) Motor Power

| 转速Rotation Speed | 外型尺寸 (mm)Overall Size | 重量(kg) Approx. Weight |

KZL160 | 120 | 1-8 | 150-450 | 1.5 | 变频调速200-1450或400-3000 Frequency 200-1450r/min or 400-3000r/min | 1000×720×1170 | 140 |

KZL180 | 135 | 1-8 | 150-550 | 1.5 | 1050×720×1200 | 160 | |

KZL200 | 140 | 1-8 | 200-700 | 1.5-2.2 | 1100×750×1300 | 190 | |

KZL250 | 180 | 1-8 | 400-1500 | 2.2-3 | 1350×800×1550 | 260 | |

KZL300 | 220 | 1-8 | 450-2500 | 5.5 | 1500×900×1700 | 400 |

Rapid Granulator: It refers to equipment whose core function remains crushing and granulating materials using a high-speed rotating rotor and a stator screen.

Therefore, the in-line rapid granulator is an on-line granulation device used in continuous production processes. Materials flow into the equipment through the pipeline, are instantly granulated inside the device, and then the granular products flow out through the pipeline into the next process.

II. Main Features

II. Main Features

Continuous Processing

Greatest Advantage: Unlike traditional "batch processing" granulators, the in-line granulator can process materials continuously, significantly improving production efficiency. It is one of the core devices embodying the modern pharmaceutical concept of "continuous manufacturing".

Fully Closed System

Dust-Free and Pollution-Free: Throughout the entire processing process, materials operate completely within the sealed pipeline, thoroughly eliminating the risks of dust leakage, external contamination, and cross-contamination. It is particularly suitable for the production of highly active, highly sensitizing (HPAPI) or sterile products.

Reduced Manual Intervention

It eliminates the large amount of manual operations required in batch processing, such as material feeding, discharging, and cleaning, reducing the risk of human error and labor costs.

III. Advantages

III. Advantages

Reduced Plant Floor Space

The equipment has a compact structure and is vertically integrated into the pipeline. Compared with independent batch equipment, it requires less cleanroom space, lowering plant construction and operation costs.

Reduced Material Loss

The closed system ensures zero dust loss, and almost all materials are converted into products. For expensive active pharmaceutical ingredients (APIs), the cost savings are quite substantial.

Energy Conservation and Consumption Reduction

Continuous production avoids energy waste caused by frequent start-ups and shutdowns of batch equipment, resulting in higher overall energy efficiency.

Summary

The in-line rapid granulator represents an advanced direction in solid preparation production. It is no longer a single-function device but a smart module seamlessly integrated into a fully automated, continuous, and closed production line. It is a key technical equipment for realizing the "industrialization" and "continuous manufacturing" of pharmaceutical production. Its selection and application are usually closely related to the design concept of the entire production line.

By continuing to use the site you agree to our privacy policy Terms and Conditions.