Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

Elevating Rotary Granulator

I. Core Definition and Working Principle

The most distinctive feature of the elevating rotary granulator is the impeller can be lifted and lowered via an electric system.

Its core working principle is identical to that of a standard rotary granulator:

Feeding: Premixed wet materials (soft mass) are added to the hopper.

Centrifugal Extrusion: When the machine is started, the rotary knife rotated. Under centrifugal force, the materials are crushed and extruded through the surrounding screen sieve.

Discharging: The extruded strip-shaped materials are cut into granules, then fall through the discharge port.

Notably, the "elevating" function itself does not work on granulation; instead, it serves as an auxiliary feature for material loading/unloading and cleaning.

II. Main Features and Advantages (Benefits of the "Elevating" Design)

The introduction of the elevating design is improved base on traditional fixed rotary granulators:

Extremely Convenient Discharging and Cleaning (Core Advantage)

Traditional Issue: For fixed granulators, discharging and cleaning require operators to reach into narrow spaces. This makes thorough cleaning difficult and often leaves material residues.

Elevating Solution: After granulation, simply press a button to lift the impeller—fully exposing the space below. The lifting blade has the function for pre-mixing.

Reduced Labor Intensity for Operators

There is no need to bend over or struggle to clean materials/equipment in narrow spaces. This significantly improves ergonomics and reduces physical strain.

Prevention of Cross-Contamination

Thorough cleaning effectively minimizes the risk of cross-contamination between different batches of products—a critical requirement for compliance with GMP (Good Manufacturing Practice).

Easy Inspection and Maintenance

When the granulation components are lifted, the wear status of consumable parts (such as screens, granulation blades, and cutting knife) can be visually inspected directly. This facilitates daily checks and maintenance.

III. Structural Components

Machine Base: Houses the motor, transmission system, and lifting mechanism.

Elevating Column: Supports and guides the stable lifting/lowering of the granulation components.

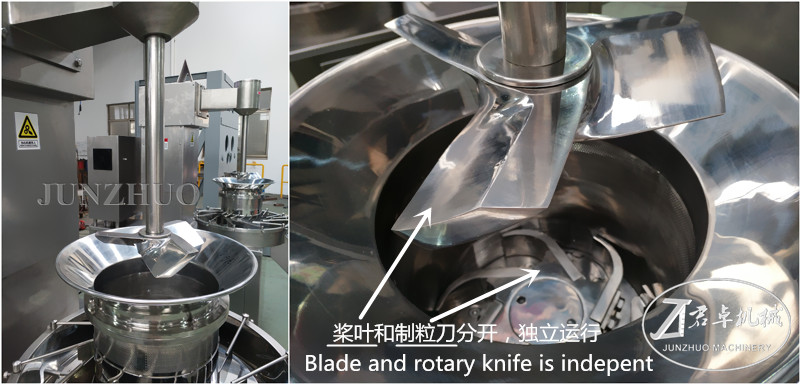

Granulation Main Head: Contains the impeller, granulation blades, cutting knives, and screen sieve—serving as the core working module of the equipment.

Hopper: Used to hold materials.

Electrical Control System: Controls the machine’s start, stop, and lifting/lowering operations. (PLC control is optional.)

IV. Applicable Scenarios

Due to its convenience, the elevating rotary granulator is particularly suitable for the following scenarios:

Pharmaceutical Industry: A common piece of equipment in solid preparation workshops, where strict requirements for equipment cleaning and cross-contamination prevention apply.

Food Industry: Production lines that require frequent product changeovers. Fast and thorough cleaning significantly improves efficiency.

Chemical Industry: Processing of fine chemical products that require contamination avoidance.

R&D and Small-to-Medium Batch Production: Scenarios involving frequent formula and material changes, where the cleaning convenience of the elevating function provides a distinct advantage.

In General

The elevating rotary granulator represents a user-centric and compliance-focused improvement over traditional rotary granulators. By the simple elevating structure, it effectively solves two problems: difficult discharging and difficult cleaning. While preserving the original granulation function, it significantly enhances operational convenience, cleaning thoroughness, and production compliance.

Although its cost may be slightly higher than fixed models, this investment is highly worthwhile for modern enterprises that prioritize product quality, production efficiency, and GMP compliance.

By continuing to use the site you agree to our privacy policy Terms and Conditions.