Copyright © 2019 JIANGYIN JUNZHUO MACHINERY MANUFACTURING CO., LTD All Rights Reserved. Site MapDesigned by iwonder.cn

jz@junzhuojx.com

jz@junzhuojx.com

+86-0510-86382380

+86-0510-86382380

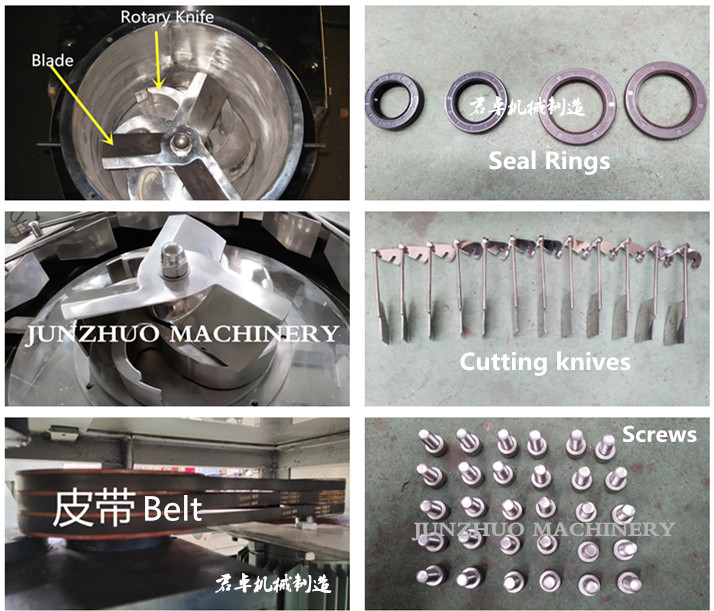

Wear Parts of Rotary Granulators & Their Maintenance

Wear parts refer to components that gradually wear, deform, or suffer fatigue damage due to mechanical actions such as friction, extrusion, and impact with materials during normal use. These parts require regular inspection and replacement to ensure equipment performance.

Below are the main wear parts of rotary granulators and key maintenance guidelines:

I. Core Working Components (Most Severe Wear)

These components are in direct contact with materials and bear the highest mechanical stress, leading to the fastest wear.

1. Screen Sieve

Function: Acts as a "mold" for granule formation, directly determining the particle size of the final product.

Wear Patterns:

Mesh holes become enlarged or deformed;

Wear at edge seals;

Severe cases may result in cracks or breaks.

Consequences: Uneven particle size, appearance of oversized granules or long strips.

Maintenance Recommendations:

This is the most frequently replaced part. Thoroughly clean it immediately after each use to prevent residual material from hardening and accelerating wear.

Inspect visually before and after each use; replace immediately if mesh holes are irregular or the screen is broken.

2. Rotary Blade

Function: Rotate to extrude materials through the screen sieve, a key component for shaping granules.

Wear Patterns:

Blade surfaces (especially edges and corners) are worn smooth;

Reduction in blade diameter due to long-term friction.

Consequences: Decreased extrusion force, leading to lower granulation efficiency, reduced output, loose granules, and excessive fine powder.

Maintenance Recommendations:

Regularly check the blade’s outer diameter and surface wear. Use calipers to measure diameter changes if needed.

Replace the blades when the gap between the blade and screen exceeds the recommended range, as adjustments cannot restore performance.

3. Scrapers/Granulating knife

Function: Scrape materials toward the extrusion rollers and clean the inner wall of the screen to prevent material adhesion and accumulation.

Wear Patterns: Scraper heads are worn down and shortened.

Consequences: Material accumulates on the inner wall of the screen, reducing granulation efficiency and even causing discharge blockages.

Maintenance Recommendations:

Check the gap between the scraper and the screen inner wall regularly. The ideal gap is 1.0mm (varies by equipment).

If wear is slight, adjust the scraper position to restore the gap; if wear is severe, replace the scraper promptly.

II. Transmission & Sealing Components

These parts ensure stable power transmission and prevent contamination, and their failure can lead to equipment shutdown or product quality risks.

4. Bearings

Location: Installed on the main shaft to support high-speed rotation of the extrusion rollers.

Wear Patterns:

Fatigue damage from long-term high-load operation;

Material dust enters the bearing due to seal failure, accelerating internal wear (abrasive wear).

Consequences: Abnormal noise, excessive heat generation, and increased vibration during operation; severe cases may cause bearing seizure and equipment shutdown.

Maintenance Recommendations:

Regularly lubricate with food-grade/pharmaceutical-grade grease (comply with GMP requirements for pharmaceutical/food use) every 200–300 operating hours. Avoid over-lubrication, which may attract dust.

Listen for abnormal sounds during operation (e.g., grinding or rattling); if detected, stop the machine immediately for inspection.

Replace bearings proactively every 1,500–2,000 operating hours (or as per the manufacturer’s recommendation), even if no obvious faults are found.

5. Seals

Function: Prevent material dust from entering the transmission box and bearings, and avoid lubricating grease leakage to contaminate materials. Common types include oil seals and O-rings.

Wear Patterns:

Rubber seals age, harden, or crack;

Seal lips wear, losing their sealing ability;

Deformation due to high temperatures or chemical corrosion(for special materials).

Consequences:

Dust contamination of bearings (accelerating bearing damage);

Grease leakage into materials (causing product quality accidents, especially in pharmaceuticals/food).

Maintenance Recommendations:

Implement preventive replacement: Replace seals every 6–12 months, or whenever bearings are replaced (even if seals appear intact), to avoid unexpected failures.

6. Drive Belts/Chains

Function: Transmit power from the motor to the main shaft, ensuring stable rotation speed.

Wear Patterns:

Belts: Stretching, slipping, surface wear, or aging (cracking);

Chains: Elongation of chain links, wear of pins and bushings, or rust.

Consequences: Reduced transmission efficiency, unstable rotation speed (affecting granule uniformity), and increased motor load.

Maintenance Recommendations:

For belts: Check tension regularly. Adjust the motor position to tighten if loose, or replace if the belt is cracked or glazed.

For chains: Lubricate with chain oil every 100 operating hours.

III. Other Components

7. Fasteners

Included Parts: Bolts, nuts, and screws that secure screens, blades, and other components.

Wear Patterns:

Loosening due to equipment vibration;

Thread stripping or deformation (from over-tightening during maintenance).

Consequences: Loose components affect equipment stability, may cause abnormal noise or vibration, and pose safety risks.

Maintenance Recommendations:

Conduct regular "tightness checks" during daily inspections, focusing on fasteners for screens and blades.

Use torque wrenches to tighten key bolts to the manufacturer’s specified torque (avoid over tightening).

Mark critical fasteners with anti-loosening paint; if the mark is misaligned, it indicates loosening.

IV. Wear Part Management Best Practices

Effective management of wear parts is critical to minimizing unplanned downtime and ensuring stable production.

1.Establish a Wear Part List

Create a detailed list for each rotary granulator, including:

Part number, specification, and manufacturer;

Recommended replacement cycle (based on operating hours or frequency of use);

Application location.

2.Maintain Safety Stock

Keep a safety stock of high-frequency replacement parts (e.g., screens, scrapers, seals) to avoid production halts due to waiting for spare parts. The stock quantity can be determined by:

Monthly replacement frequency;

Lead time for purchasing.

3.Implement Preventive Maintenance (PM) Plans

Set up a PM schedule.

Record maintenance and replacement history to predict part life and avoid sudden failures.

4.Choose High-Quality Replacement Parts

Prioritize original equipment manufacturer (OEM) parts or certified compatible parts. Although their upfront cost may be 10–30% higher than low-cost alternatives, they offer longer service life (2–3 times longer in some cases) and better compatibility, reducing total maintenance costs.

Avoid using non-standard parts for pharmaceutical/food applications, as they may not meet hygiene or precision requirements.

5.Train Operators

Train operators on proper equipment use. Such as avoiding idling or overloading of the equipment, can effectively extend the service life of vulnerable parts.

Teach basic inspection skills so operators can report issues promptly.

Summary

Managing the wear parts of rotary granulators is a key link to achieving efficient, stable, and low-cost production. Through preventive maintenance, regular replacement and good operating habits, unexpected shutdowns can be minimized to ensure the continuous stability of product quality.

For high-compliance industries (e.g., pharmaceuticals), strict adherence to wear part replacement records and GMP requirements (e.g., using food-grade lubricants) is also critical to meeting regulatory standards.

By continuing to use the site you agree to our privacy policy Terms and Conditions.